Manufacturing performance is often judged by output numbers, but high production does not always mean high efficiency. Machines may be running, yet losses from downtime, slow cycles, and quality issues quietly reduce profitability. This is why leading manufacturers rely on Overall Equipment Effectiveness (OEE) to measure true operational performance.

OEE provides a clear, data-driven way to understand how effectively equipment is being used and where improvement opportunities exist. In this blog, we explain what OEE is, OEE calculation, and how to improve OEE using a structured approach and an intelligent OEE monitoring system, with practical support from Devanta Tech.

What Is OEE and Why Is It Important?

Overall Equipment Effectiveness (OEE) is a standard manufacturing metric that measures the percentage of planned production time that is truly productive. Instead of focusing on one problem at a time, OEE highlights all major production losses in a single, easy-to-understand score.

OEE is built on three key components:

- Availability – Equipment uptime versus planned production time

- Performance – Actual production speed compared to ideal speed

- Quality – Good products produced without defects or rework

Together, these factors reveal whether losses are coming from downtime, inefficiencies, or quality issues—making OEE a powerful tool for continuous improvement.

OEE Calculation: Understanding the Formula

The standard OEE calculation formula is:

OEE = Availability × Performance × Quality

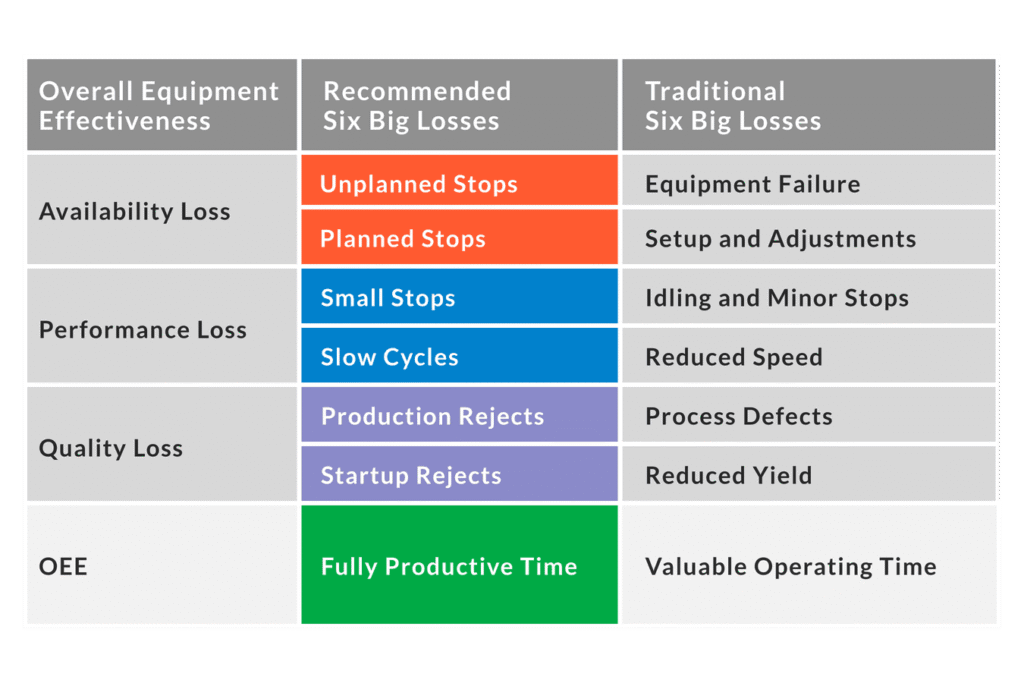

Each factor addresses a specific loss category:

- Availability identifies losses due to breakdowns, changeovers, and waiting time

- Performance highlights speed losses and micro-stoppages

- Quality captures losses from scrap and rework

For example, even if each factor performs reasonably well on its own, small inefficiencies across all three can significantly lower the final OEE score. This is why OEE uncovers issues that traditional production reports often miss.

Common Challenges in Improving OEE

Many manufacturers struggle to improve OEE due to:

- Manual data collection and delayed reporting

- Lack of real-time visibility into machine performance

- Inconsistent downtime classification

- Limited historical data for trend analysis

Without accurate and timely information, improvement efforts become reactive and short-lived.

How to Improve OEE in a Sustainable Way

To improve OEE, manufacturers must shift from manual tracking to real-time, data-driven monitoring. Key improvement strategies include:

- Capturing downtime reasons directly from the shop floor

- Identifying performance losses at the machine and line level

- Monitoring quality trends to reduce defects early

- Comparing OEE across shifts, machines, and plants

- Enabling teams to take immediate corrective actions

An effective OEE monitoring system is essential to support these actions consistently.

OEE Monitoring System: Turning Insights into Action

An OEE monitoring system automatically collects production data and calculates OEE in real time. It provides live dashboards, alerts, and reports that help supervisors and management respond quickly to losses.

Manufacturers using OEE monitoring systems benefit from:

- Improved transparency and accountability

- Faster root cause analysis

- Measurable and continuous performance improvement

This approach is widely adopted across Automotive & Auto Components, Manufacturing & Discrete, Electrical & Electronics, and Process & Chemicals industries.

How Devanta Tech Supports Your OEE Journey

At Devanta Tech, we help manufacturers implement reliable OEE solutions aligned with their operational goals.

Our Process & Services:

- Assessment & Consulting – Understanding production challenges and defining OEE KPIs

- OEE Monitoring System Implementation – Customized dashboards and reports

- OT Software Implementation & Data Historian – Centralized data for accurate OEE calculation

- Industrial Hardware Sales & Installation – Robust infrastructure for data capture

- Engineering, Consulting & Training – Empowering teams to use OEE data effectively

Start Improving Your OEE Today

If you want consistent productivity improvements without increasing operational costs, OEE is the right metric—and Devanta Tech is the right partner.

Connect with Devanta Tech to implement a scalable OEE monitoring system for your plant.

Frequently asked questions (FAQs)

1. What is a good OEE score for manufacturers?

An OEE score of 85% or higher is considered world-class, but steady improvement is the real goal.

2. Can OEE be improved without adding new machines?

Yes. Most OEE gains come from reducing downtime, speed losses, and quality issues.

3. Why is an OEE monitoring system important?

It provides real-time visibility and accurate data, enabling faster and better decisions.