Indian manufacturing is going through a major transformation. Rising operational costs, frequent machine breakdowns, and quality inconsistencies are pushing factories to rethink how they operate. This is where factory automation in India is playing a crucial role.

Factory automation is no longer limited to large enterprises. Today, even small and mid-sized manufacturers are adopting automation to improve productivity, reduce downtime, and stay competitive.

In this guide, we explain what factory automation is, why it matters, and how Devanta Tech supports manufacturers with reliable factory automation solutions.

What Is Factory Automation?

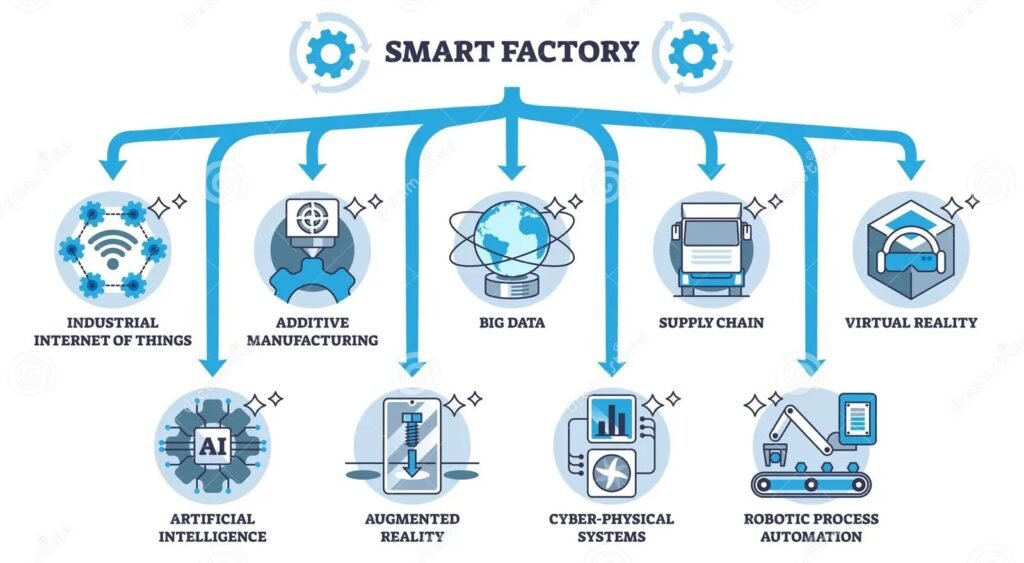

Factory automation is the use of control systems, software, and connected industrial devices to automate manufacturing processes. Instead of depending on manual monitoring and intervention, machines operate intelligently with real-time data and predefined logic.

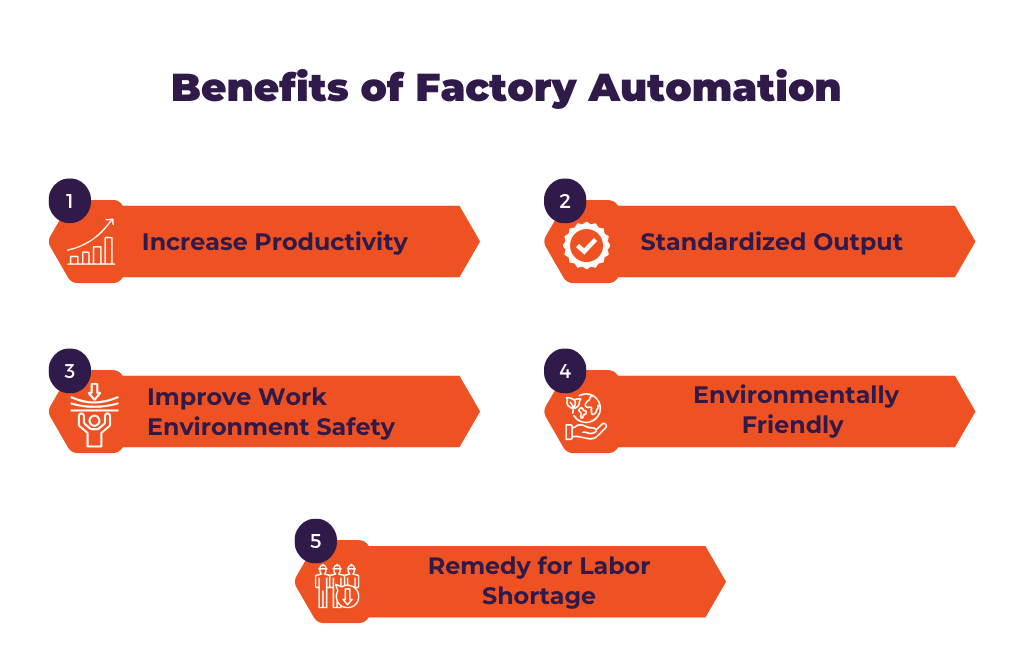

Automation helps manufacturers:

- Reduce human errors

- Improve production efficiency

- Ensure consistent product quality

- Gain real-time visibility of operations

With the rise of factory automation in India, manufacturers are moving from reactive operations to data-driven decision-making.

Why Factory Automation in India Is Growing Rapidly

The demand for factory automation in India is increasing due to several challenges faced by manufacturers:

- Unplanned downtime and equipment failures

- Lack of real-time production data

- High energy consumption

- Skilled labour shortages

Automation addresses these issues by creating connected, intelligent factories that can monitor performance, predict failures, and optimize processes automatically.

This is why choosing the right partner from experienced industrial automation companies becomes critical.

Core Factory Automation Solutions Used by Manufacturers

Modern factory automation solutions include a combination of hardware, software, and analytics tools, such as:

- PLC and SCADA systems for control and monitoring

- Industrial sensors and instrumentation

- IIoT platforms for real-time data visibility

- Energy monitoring systems

- Predictive maintenance solutions

However, the real value of automation lies in integration, not just individual technologies.

How Devanta Tech Delivers Factory Automation Solutions

At Devanta Tech, we focus on practical, result-oriented automation tailored to Indian manufacturing needs.

1. Process Assessment & Requirement Study

We start by understanding your existing plant setup, operational challenges, and business goals. This ensures the automation strategy aligns with real-world requirements.

2. Customized Automation Design

Our team designs factory automation solutions that match your production flow—whether you operate in process industries, discrete manufacturing, or utilities.

3. System Integration & Connectivity

We integrate machines, control systems, and data sources into a unified platform, enabling seamless monitoring and control across the factory.

Explore our Industrial Automation Services page to understand our integration approach.

4. Deployment, Testing & Training

We ensure smooth implementation with minimal disruption. Operators and engineers are trained to use the system confidently.

5. Support, Optimization & Scalability

Devanta Tech provides long-term support to optimize system performance and scale automation as your factory grows.

Learn how our IIoT & Smart Factory Solutions help manufacturers achieve real-time visibility.

Why Devanta Tech Among Industrial Automation Companies?

Among many industrial automation companies, Devanta Tech stands out because:

- We understand Indian factory environments

- We focus on ROI-driven automation

- We offer end-to-end services—from design to support

- We build scalable solutions for future expansion

Our goal is to help manufacturers move from basic automation to smart, connected factories.

Discover why manufacturers trust Devanta Tech for automation projects.

Conclusion

Factory automation is transforming manufacturing efficiency, quality, and decision-making. With the rapid growth of factory automation in India, manufacturers who invest early gain a strong competitive advantage.

By partnering with Devanta Tech, you get reliable factory automation solutions backed by expertise, integration capability, and long-term support.

Frequently asked questions [FAQs]

1. Are factory automation solutions suitable for small Indian manufacturers?

Yes. Devanta Tech designs scalable automation that fits small and mid-sized factories without heavy upfront investment.

2. How do industrial automation companies help reduce downtime?

By integrating real-time monitoring, predictive maintenance, and automated alerts, downtime can be significantly reduced.

3. Is factory automation in India expensive to implement?

Costs depend on scope and scale. With phased implementation, automation becomes cost-effective and delivers quick ROI.