On most factory floors, problems don’t start at the top—they start silently on the shop floor. A machine slows down, a line stops briefly, quality drops for one shift, or data gets recorded late. By the time management notices, losses have already occurred.

This is why shop floor automation is becoming a necessity rather than an upgrade. It helps manufacturing plants move from delayed reporting to real-time visibility, enabling faster decisions and better control. In this guide, we explain how shop floor automation works, why shop floor digitization matters, and how Devanta Tech supports manufacturers through a practical, result-driven approach.

What Does Shop Floor Automation Really Mean?

Shop floor automation is not only about machines or controls. It is about capturing accurate production data directly from the shop floor and using it to improve daily operations.

With shop floor automation, plants can:

- Monitor production status in real time

- Identify downtime and losses immediately

- Reduce dependency on manual registers and shift reports

When combined with shop floor digitization, operational data becomes structured, reliable, and accessible—creating a strong foundation for improvement.

See how reliable systems and proper setup support shop floor automation through Industrial Hardware Sales & Installation

Why Shop Floor Digitization Changes the Way Plants Operate

Many factories still rely on Excel sheets or end-of-shift updates. This delay hides inefficiencies and limits corrective action.

Shop floor digitization enables:

- Live tracking of machines, lines, and shifts

- Clear visibility of production targets vs actual output

- Faster coordination between production and maintenance teams

Instead of reacting after losses occur, teams can take action while production is running.

Understand how production data is captured and structured using OT Software Implementation & Data Historian

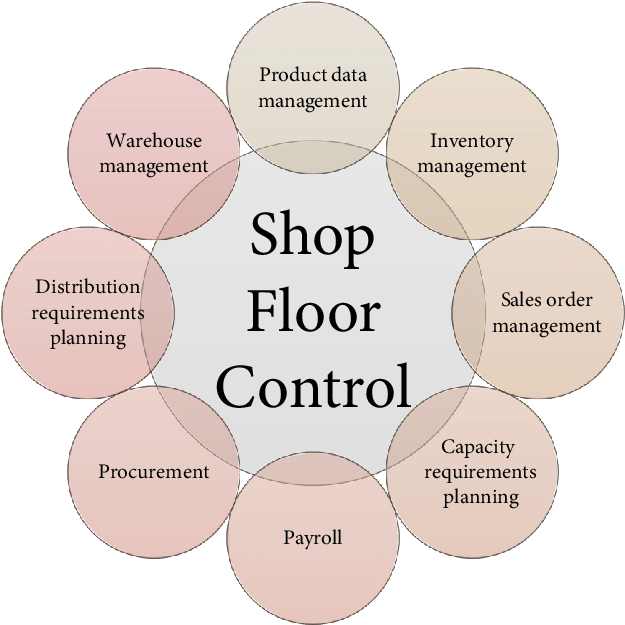

Role of a Shop Floor Management System

A shop floor management system brings all shop floor data into a single, easy-to-understand view. It helps supervisors and managers focus on what truly matters.

With a shop floor management system, manufacturers can:

- Track daily production performance

- Analyze downtime causes and trends

- Improve operator accountability

- Support continuous improvement initiatives

The system turns raw data into insights that drive consistent, measurable results.

How Devanta Tech Approaches Shop Floor Automation

At Devanta Tech, we focus on practical implementation, not complexity. Our solutions are designed to fit real plant environments and scale with business needs.

What Devanta Tech Provides

- Customized shop floor automation solutions

- Complete shop floor digitization for accurate data flow

- User-friendly shop floor management systems

- Seamless integration with existing operations

- Ongoing optimization and support

Explore our end-to-end execution model under Turnkey Automation & IIoT Solutions

Devanta Tech’s Implementation Process

We follow a structured approach to ensure smooth adoption and long-term value:

- Assessment & Gap Analysis

Understanding current processes, losses, and reporting gaps. - Solution Design

Creating a roadmap aligned with plant goals and operational realities. - System Deployment

Implementing digitization and management systems with minimal disruption. - Training & Enablement

Ensuring operators and supervisors confidently use the system. - Performance Improvement

Using insights to reduce downtime, improve productivity, and sustain results.

Learn how our experts guide teams through adoption via Engineering, Consulting & Training

Industry-Focused Solutions

Devanta Tech supports a wide range of manufacturing sectors, including:

Automotive & Auto Components, Manufacturing & Discrete, Electrical & Electronics, Machinery & Equipment Manufacturing, Packaging Industry, and Process & Chemicals—each with tailored shop floor solutions.

Take Control of Your Shop Floor

If your plant struggles with delayed data, unclear performance, or recurring inefficiencies, shop floor automation can transform your operations—starting today.

Connect with Devanta Tech to build visibility, control, and confidence across your shop floor.

Frequently asked questions (FAQs)

1. Is shop floor automation suitable for existing plants?

Yes. Shop floor automation can be implemented in phases without stopping production.

2. What is the main benefit of shop floor digitization?

It provides real-time visibility, enabling faster decisions and immediate corrective actions.

3. How long does it take to see results?

Most plants begin to see operational improvements within weeks of implementation.