Production losses don’t always come from major machine breakdowns. Often, they start with small, repeated issues—short stoppages, slow cycles, or material delays. Individually, these seem minor, but together they reduce efficiency, output, and profitability.

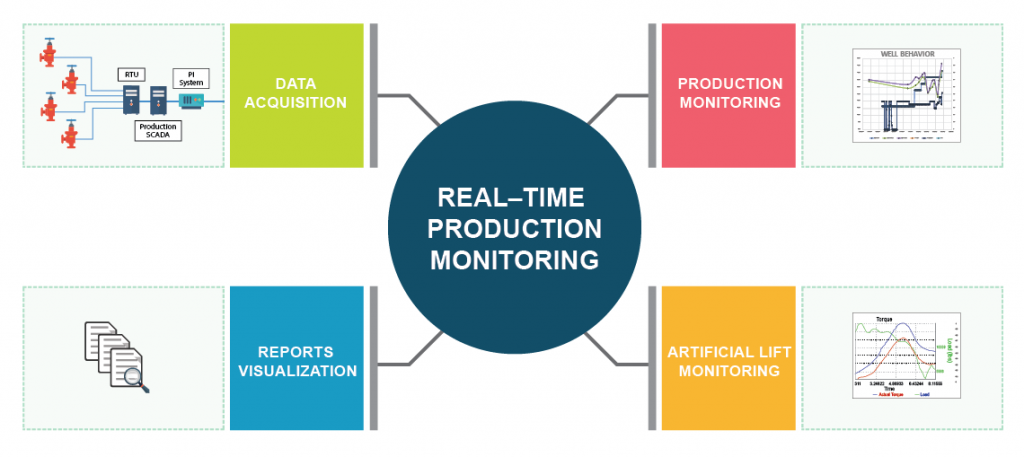

A production monitoring system solves this problem by providing real-time production monitoring, allowing supervisors and management to track machines, lines, and operators instantly. This blog explains what a production monitoring system is, why it’s important, and how Devanta Tech implements practical solutions to improve production control.

Understanding a Production Monitoring System

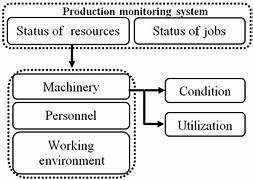

A production monitoring system is a digital platform that tracks, records, and analyzes shop floor activity. Instead of relying on manual logs or end-of-shift reports, it provides live insights on:

- Machine and line performance

- Production output vs planned targets

- Downtime reasons and duration

- Shift-wise and operator performance

By converting raw data into actionable insights, plants can identify problems immediately and make faster decisions.

Why Real-Time Production Monitoring Matters

Traditional reporting methods only show what went wrong after the fact. By the time data reaches management, it’s often too late to prevent losses.

Real-time production monitoring changes this by:

- Highlighting stoppages and slowdowns instantly

- Allowing supervisors to respond during production

- Reducing unplanned downtime and losses

- Improving coordination between production and maintenance

Reliable monitoring starts with proper infrastructure—learn more under Industrial Hardware Sales & Installation

Example: Packaging Plant

A packaging plant operates three shifts with multiple machines.

Before a monitoring system:

- Operators recorded production manually

- Downtime reasons were inconsistent

- Management received reports hours later

- Maintenance acted only after issues escalated

After implementing a production monitoring system with production tracking software:

- Machines automatically reported their status

- Dashboards displayed live production output

- Downtime alerts appeared immediately

- Supervisors monitored shift performance in real time

Scenario: At 11:20 AM, a machine stops. The system sends an alert, and maintenance fixes the issue in 10 minutes instead of 45. Losses are minimized instantly.

See how data is captured and analyzed via OT Software Implementation & Data Historian

Role of Production Tracking Software

Production tracking software collects shop floor data and presents it in dashboards and reports. It helps teams:

- Compare actual vs planned production

- Identify recurring downtime causes

- Monitor operator and shift performance

- Track trends over days, weeks, or months

Example Insight: The system shows Shift B consistently loses 20 minutes due to material delays. Management can now act immediately to fix the root cause.

How Devanta Tech Implements Production Monitoring Systems

At Devanta Tech, we design systems that are practical, scalable, and easy to use:

- Custom production monitoring systems

- Accurate real-time production monitoring

- User-friendly production tracking software

- Seamless integration with existing equipment

- Ongoing optimization for consistent performance

Explore our solutions under Turnkey Automation & IIoT Solutions

Devanta Tech’s Implementation Process

- Assessment – Identify current gaps and losses.

- Solution Design – Tailor the monitoring system to plant requirements.

- Deployment – Install dashboards and software with minimal disruption.

- Training – Ensure smooth adoption by operators and supervisors.

- Continuous Improvement – Use insights to reduce downtime and improve efficiency.

Learn how our experts guide teams through adoption via Engineering, Consulting & Training

Industry Applications

Our solutions are applied across Automotive & Auto Components, Manufacturing & Discrete, Electrical & Electronics, Machinery & Equipment Manufacturing, Packaging Industry, and Process & Chemicals, customized for each environment.

Frequently asked questions (FAQ’s)

1. Can a production monitoring system integrate with existing machines?

Yes. Devanta Tech systems can be retrofitted to legacy equipment without major modifications.

2. How quickly will improvements be seen?

Most plants notice increased efficiency and reduced downtime within weeks.

3. What is the main advantage of real-time production monitoring?

It allows immediate corrective action, preventing minor issues from escalating. Take Control of Production