In today’s competitive environment, manufacturing plants can no longer afford unexpected equipment failures. Traditional maintenance approaches often react after problems occur, leading to downtime, production delays, and higher costs. This is why predictive maintenance in manufacturing is gaining attention as a smarter and more reliable maintenance strategy.

Predictive maintenance focuses on monitoring actual machine conditions and identifying early warning signs of failure. Instead of depending on fixed schedules or emergency repairs, manufacturers can plan maintenance activities based on real operational data.

Why Predictive Maintenance in Manufacturing Is Becoming Critical

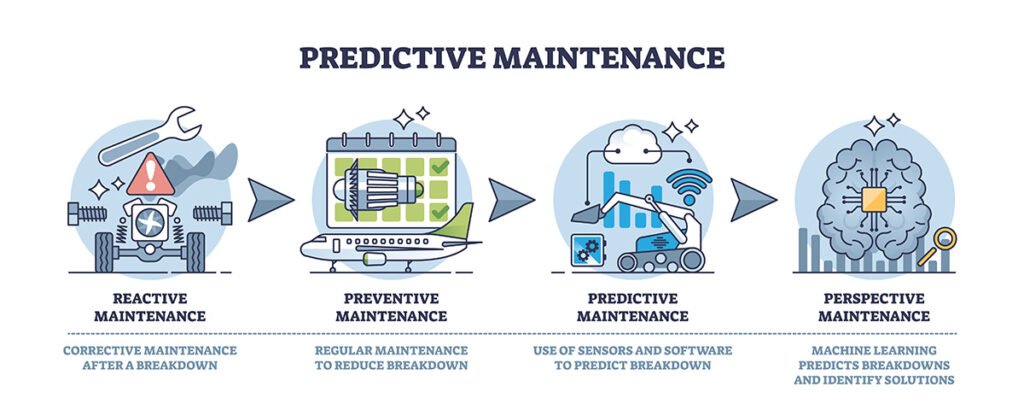

As production systems grow more complex, reactive and preventive maintenance methods struggle to deliver consistent results. Reactive maintenance causes sudden stoppages, while preventive maintenance can result in unnecessary servicing. Predictive maintenance in manufacturing addresses both challenges by enabling timely, data-backed maintenance decisions.

By adopting predictive maintenance, manufacturers can:

- Reduce unplanned downtime

- Improve maintenance planning accuracy

- Optimise resource and spare-part usage

- Increase equipment reliability and lifespan

This approach allows maintenance teams to move away from firefighting and toward structured, proactive maintenance.

Predictive Maintenance in Manufacturing: How It Works

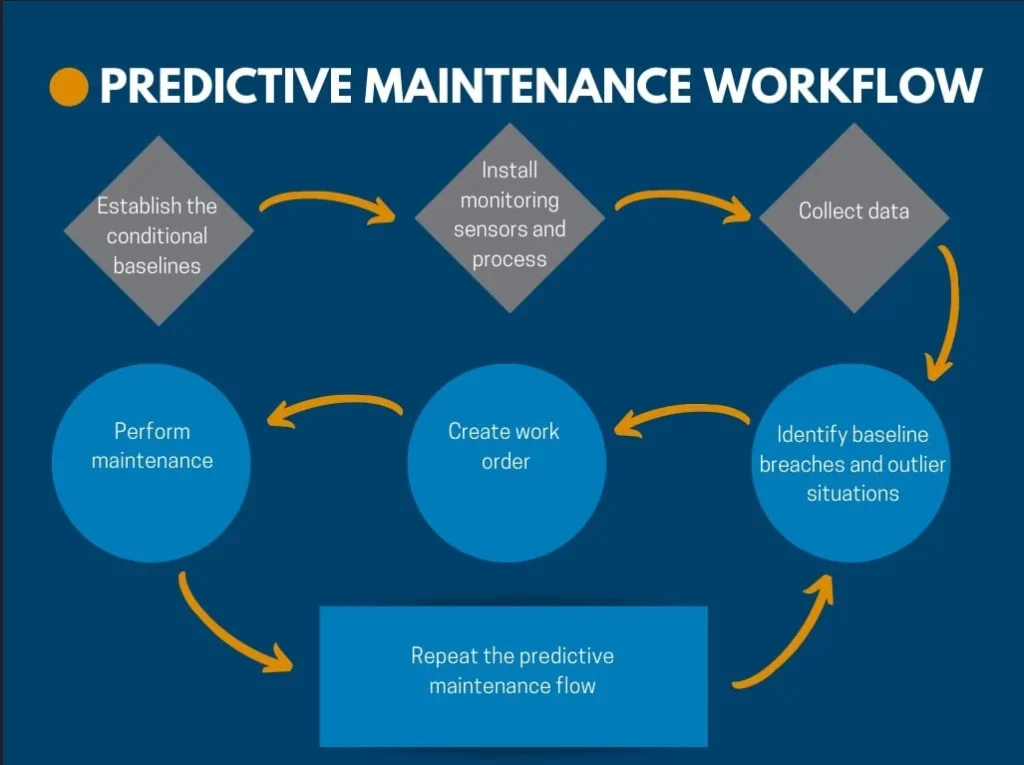

At a practical level, predictive maintenance in manufacturing involves continuous monitoring of equipment behaviour. Machine data is analysed to detect deviations from normal performance patterns. When early signs of failure appear, maintenance teams can intervene before breakdowns occur.

This method improves coordination between production and maintenance teams and ensures that maintenance actions support production goals instead of interrupting them.

Predictive Maintenance Using IIoT

A major enabler of modern predictive maintenance is predictive maintenance using IIoT. IIoT connects machines, systems, and software to enable real-time data exchange across the plant.

With predictive maintenance using IIoT, manufacturers gain:

- Continuous visibility into equipment health

- Centralised access to machine and process data

- Early identification of abnormal operating conditions

- Better understanding of long-term performance trends

By using predictive maintenance using IIoT, maintenance decisions are no longer based on assumptions but on actual machine behaviour.

Maintenance Automation: Turning Insights into Action

Data visibility alone does not prevent failures. This is where maintenance automation plays a critical role. Maintenance automation ensures that once potential issues are identified, actions are triggered automatically.

Through maintenance automation, manufacturers can:

- Generate automatic alerts for abnormal conditions

- Prioritise maintenance tasks based on severity

- Reduce manual monitoring and reporting

- Improve response time and consistency

When combined with predictive insights, maintenance automation transforms maintenance from a manual process into a structured and reliable workflow.

Devanta Tech’s Approach to Predictive Maintenance

At Devanta Tech, predictive maintenance is built around outcomes—not just technology. We help manufacturers adopt predictive maintenance in manufacturing through a structured, insight-driven approach that supports production continuity. Our focus is on ensuring maintenance actions are planned, measurable, and aligned with real shop-floor conditions.

Our Process & Services

Assessment & Engineering Consulting

We begin by understanding equipment criticality, maintenance challenges, and operational priorities. Clear objectives and KPIs are defined to support predictive maintenance initiatives.

Engineering, Consulting & Training

Industrial Hardware Sales & Installation

Reliable predictive maintenance depends on stable data capture. We support plants with robust infrastructure required for predictive maintenance using IIoT.

OT Software Implementation & Data Historian

We implement OT software platforms and data historians to centralise machine and process data, enabling accurate analysis and reporting.

Turnkey Automation & IIoT Solutions

Our solutions combine IIoT connectivity with analytics and maintenance automation, enabling condition monitoring, predictive insights, and automated alerts.

Training & Continuous Improvement

We train teams to interpret data correctly and use maintenance automation tools effectively for continuous improvement.

Predictive Maintenance as a Long-Term Strategy

Predictive maintenance is not just about avoiding breakdowns—it is about building a resilient maintenance strategy. By combining predictive maintenance using IIoT with structured processes and maintenance automation, manufacturers gain better control over assets and maintenance planning.

Over time, predictive maintenance in manufacturing becomes a foundation for improved reliability, cost control, and operational stability.

Frequently asked questions (FAQs)

1. How is predictive maintenance in manufacturing different from preventive maintenance?

Predictive maintenance uses real-time data to determine maintenance needs, while preventive maintenance follows fixed schedules.

2. Does predictive maintenance using IIoT require stopping machines?

No. Data is collected during normal operation without disrupting production.

3. What role does maintenance automation play in predictive maintenance?

Maintenance automation ensures insights lead to timely alerts, faster decisions, and consistent maintenance actions.