Packaging Industry

Real-time intelligence for efficient, accurate, compliant, sustainable packaging.

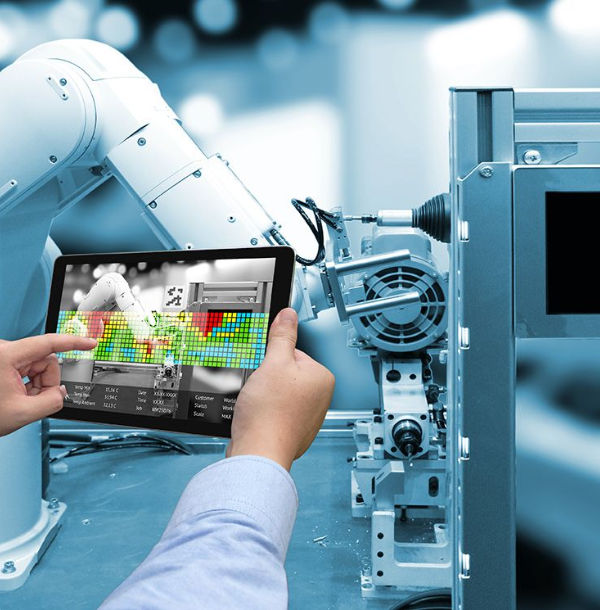

Meet rising SKU complexity and speed-to-shelf demands with connected packaging operations. We integrate IIoT, MES/SCADA, and AI-driven inspection to improve OEE, cut waste and giveaway, and ensure end-to-end traceability—from primary packaging through case packing, palletizing, and shipment across FMCG/CPG, food & beverage, pharma, and cosmetics.

Real time Perfomance Report send

User Friendly SEO Dashboard

Local SEO & Business Integrations

Social Media Integration and Sharing

Key Industry Challenges

Machinery manufacturing challenges: managing ETO/CTO complexity, long lead times, and quality compliance.

Quality & compliance pressure

-

FSMA/GMP/FDA, UDI/GS1, allergen and expiry controls require airtight traceability.

FSMA/GMP/FDA, UDI/GS1, allergen and expiry controls require airtight traceability.

Labeling & coding accuracy

-

Misprints and barcode failures trigger rework, recalls, and chargebacks.

Misprints and barcode failures trigger rework, recalls, and chargebacks.

Waste, giveaway & sustainability

-

Overfill, material scrap, and energy usage inflate costs and miss ESG goals.

Overfill, material scrap, and energy usage inflate costs and miss ESG goals.

Our Solutions

IIoT, MES/SCADA, and AI/ML to raise OEE, shorten lead times, and deliver audit-ready quality and genealogy.

Strategic Outcomes

Business Impact

Quantifiable gains in efficiency, uptime, and quality—driven by automation, predictive insights, and connected operations.

- +10–25% OEE via real-time visibility, line balancing, and fewer microstops.

- −15–30% changeover time with digital recipes and guided verification.

- −10–20% material waste & giveaway through SPC and closed-loop control.

- Fewer chargebacks & recalls by eliminating label/coding defects and ensuring compliance.

- Improved sustainability metrics (energy per unit, scrap rate) with continuous monitoring.