Walk into any manufacturing plant, and you will see machines running, operators busy, and production moving forward. However, what is not always visible are the small inefficiencies that build up in the background—unexpected stoppages, idle machines, performance drops, or early signs of wear. Without clear visibility, these issues quietly impact productivity and costs. This is why a machine monitoring system has become a critical foundation for modern manufacturing.

A machine monitoring system does not just show numbers on a screen. It provides plant teams with real-time awareness of how machines are actually performing, enabling them to take control instead of reacting late.

Why Manufacturing Plants Need Machine Monitoring Today

Most plants still depend on manual logs, shift reports, or delayed data to understand production performance. By the time issues are identified, losses have already occurred. A machine monitoring system changes this by providing live operational data directly from the shop floor.

With this visibility, manufacturers can immediately see:

- Which machines are running, idle, or stopped

- Where production losses are occurring

- How performance varies across shifts

- When abnormal conditions start developing

This level of insight enables faster decisions and more stable production.

Beyond Machines: Asset and Condition Visibility

Monitoring should not stop at machine status alone. A complete monitoring strategy also includes an asset monitoring system and a condition monitoring system.

An asset monitoring system focuses on the long-term performance and availability of critical equipment. It helps manufacturers understand asset utilisation, maintenance history, and reliability trends over time.

A condition monitoring system looks deeper into how machines behave during operation. It identifies deviations from normal conditions that may indicate stress, degradation, or early-stage faults.

When a machine monitoring system works together with an asset monitoring system and a condition monitoring system, manufacturers gain both immediate visibility and long-term operational intelligence.

How a Machine Monitoring System Creates Real Impact

A machine monitoring system continuously collects operational data and converts it into clear dashboards and reports. Supervisors and managers can:

- Track live machine status

- Compare performance across lines or shifts

- Identify repeated stoppages or inefficiencies

- Detect abnormal patterns early

With support from a condition monitoring system, maintenance teams can act before failures occur. At the same time, an asset monitoring system ensures data is used for better planning and asset optimisation.

Instead of guessing, teams work with facts.

Devanta Tech’s Approach to Monitoring Systems

At Devanta Tech, we approach monitoring with one clear objective—making shop-floor data useful and actionable. We design solutions that fit plant operations, not complex systems that sit unused.

How We Deliver Value

Assessment & Engineering Consulting

We begin by understanding your production flow, critical assets, and operational challenges. Monitoring goals and KPIs are clearly defined.

Engineering, Consulting & Training

Industrial Hardware Sales & Installation

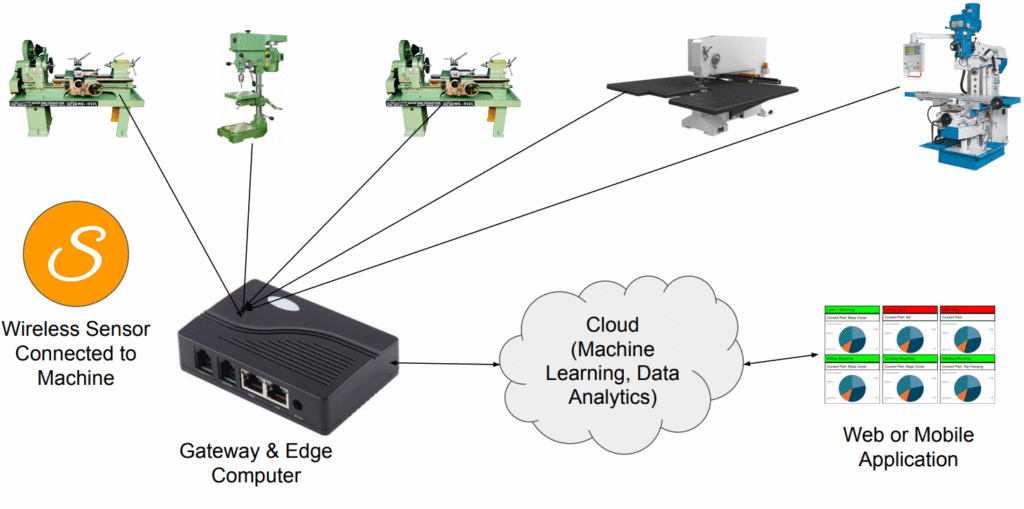

Accurate monitoring depends on reliable infrastructure. We support robust industrial hardware installation for consistent and stable data capture.

OT Software Implementation & Data Historian

We implement OT software platforms and data historians to centralise machine, asset, and condition data for analysis and reporting.

Integrated Monitoring Solutions

Our solutions combine a machine monitoring system with an asset monitoring system and a condition monitoring system to provide complete operational visibility.

Turnkey Automation & IIoT Solutions

Training & Continuous Improvement

We train teams to understand dashboards, interpret trends, and use insights for daily decision-making and continuous improvement.

Engineering, Consulting & Training

From Visibility to Control

A machine monitoring system is the first step toward operational control. When combined with an asset monitoring system and a condition monitoring system, manufacturers move from reactive responses to planned actions.

The result is better uptime, improved coordination between teams, and more predictable production outcomes—without increasing operational complexity.

Frequently asked questions (FAQs)

1. Is a machine monitoring system useful without automation upgrades?

Yes. Monitoring systems can work with existing equipment and provide value without major changes.

2. How does a condition monitoring system support maintenance planning?

It detects early signs of abnormal behaviour, allowing maintenance to be planned instead of reactive.

3. Can an asset monitoring system grow with plant expansion?

Yes. Asset monitoring systems are scalable and can expand across machines, lines, or plants.