Energy costs are one of the biggest expenses for modern manufacturing plants—especially in Malta, where electricity prices are among the highest in Europe. Yet most factories still track energy at a building or department level, which is far too broad to pinpoint inefficiencies or hidden waste. Machine-level energy monitoring changes that completely, giving plant managers and operators clear, actionable insights into every machine on the floor.

With real-time monitoring, factories gain visibility into individual machine energy consumption, allowing them to identify waste, prevent unnecessary costs, and optimize production processes. In today’s competitive environment, this level of insight is no longer optional—it’s essential.

Why Energy Visibility Matters

Traditional energy tracking methods—like monthly utility bills or floor-wide meters—leave factories in the dark. Without machine-level data, it’s impossible to know:

- Which machines are consuming the most energy

- Which equipment runs idly unnecessarily

- When peak load hours occur

- Hidden maintenance issues revealed through abnormal energy spikes

Without this visibility, energy inefficiencies remain unnoticed, and plants end up paying for wasted energy month after month. For Malta-based manufacturers, where energy costs are a significant portion of operational expenses, this can quickly add up to lakhs per year.

What Is Machine-Level Energy Monitoring?

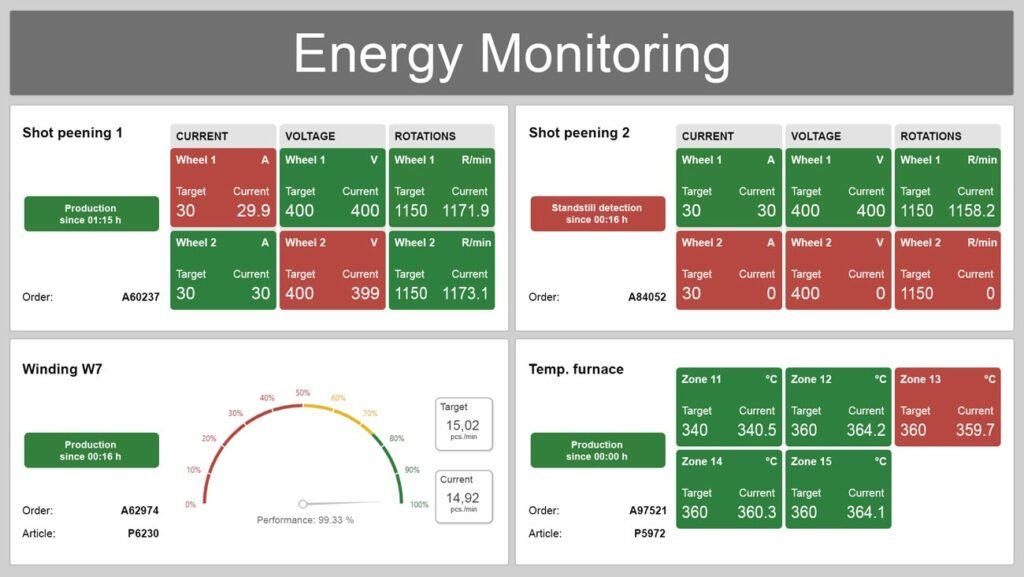

Machine-level energy monitoring uses IIoT sensors and smart meters to track real-time energy usage of individual machines, rather than providing only aggregate data. It allows you to see:

- Energy consumption per machine

- Idle time and unnecessary usage

- Abnormal spikes indicate mechanical or operational issues

- Load variations during different production cycles

This transforms energy monitoring from passive reporting into proactive management, giving each machine a “smart voice” to alert you when something isn’t running efficiently.

Explore our industrial hardware solutions.

Key Benefits for Modern Plants

1. Reduce Energy Waste

Identify machines consuming excess energy and take immediate action. This is particularly valuable for high-energy devices like motors, compressors, and pumps.

2. Lower Operational Costs

Even small improvements can save thousands of euros per month. Energy-efficient operations directly impact the bottom line.

3. Predict Maintenance Needs

Abnormal energy spikes often signal mechanical issues such as misaligned motors, worn bearings, or inefficient startup sequences. Early detection helps prevent unplanned downtime.

4. Increase OEE and Productivity

Energy insights reveal inefficiencies in machine use, shift patterns, and process scheduling. Optimizing operations based on these insights improves overall equipment effectiveness (OEE) without adding new machines or staff.

5. Support Sustainability Goals

Energy transparency helps plants comply with environmental regulations and sustainability targets, contributing to a greener manufacturing footprint.

Learn more about our OT software & data historian services.

Small Actions, Big Savings

Energy waste is often hidden in day-to-day operations:

- Compressors left running during breaks

- Machines were powered on unnecessarily after shifts

- Motors are working inefficiently due to poor calibration

- Pumps consume extra energy during startup or overload

With machine-level monitoring, these issues are revealed instantly, allowing teams to take corrective action and reduce costs immediately.

See how our turnkey IIoT solutions improve energy efficiency.

Getting Started

Implementation is simpler than most think. You don’t need to replace your machines or overhaul your electrical infrastructure. Start with:

- Monitoring the top 5 energy-consuming machines

- Installing plug-and-play IIoT energy sensors

- Tracking real-time usage on dashboards

- Setting up automated alerts for abnormal consumption

- Gradually expanding monitoring across the plant

With this approach, plants can start saving energy quickly while building confidence for broader IIoT adoption.

Check out our consulting & training services to implement IIoT monitoring smoothly.

Conclusion

Machine-level energy monitoring is no longer a luxury—it’s a necessity for modern, cost-conscious, and sustainable manufacturing. By giving plants detailed, real-time insights into machine energy consumption, it enables better decision-making, reduces waste, extends equipment life, and ensures smoother, more efficient operations.

For plants in Malta and beyond, adopting machine-level energy monitoring provides a clear competitive edge: lower costs, improved efficiency, and smarter operations.

Contact our IIoT specialists for a free consultation.