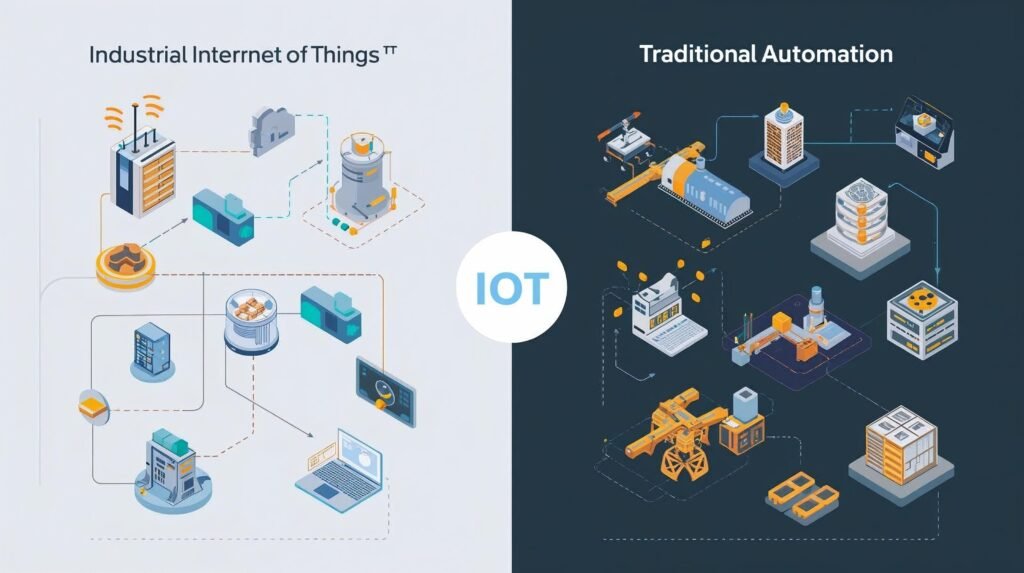

For decades, traditional automation has been the backbone of industries — machines programmed to follow fixed logic, PLC-controlled lines, and operators ensuring everything stayed on track.

But today, industries are moving beyond “machines that follow commands” to “machines that communicate, analyse, and optimize themselves.”

This shift is powered by IIoT, and it’s completely changing how modern factories think, work, and grow.

1. From Fixed Processes to Adaptive Systems

Traditional automation follows predefined steps.

If a situation changes — load increases, temperature rises, or material varies — the system doesn’t adjust automatically. IIoT works differently. Machines continuously sense what’s happening around them and make micro-adjustments in real time.

Example:

In a packaging plant, if material thickness suddenly changes, IIoT-enabled systems adjust pressure instantly instead of waiting for an operator to intervene.

To understand how advanced automation adapts in real plants, explore our automation & IIoT offerings.

2. From Limited Visibility to Real-Time Transparency

Traditional automation tells you only when something goes wrong. IIoT shows what’s happening right now. Every motor, conveyor, pump, and sensor becomes part of a transparent network.

Teams can see:

- live production rate

- energy consumption

- quality variations

- machine health

- downtime reasons

This level of transparency enables companies to avoid delays, enhance planning, and make more informed decisions.

For deeper monitoring and hardware integration options, visit our Industrial Hardware & Installation page.

3. From Scheduled Maintenance to Predictive Maintenance

Old systems depend on a calendar. Machines are checked monthly or quarterly — even if they don’t need service. IIoT works on actual conditions, not guesswork. It tracks vibration, pressure, temperature, load, and hundreds of microdata points to predict failures before they happen. This shift reduces unplanned downtime and extends machine life significantly.

4. Better Collaboration Across the Entire Factory

Traditional automation works in silos — production, quality, and maintenance act separately. IIoT connects everything. A quality issue on Line 1 is instantly visible to the maintenance team. A sensor alert becomes a live notification for supervisors. Energy spikes get recorded for analysis. This improves teamwork, reduces confusion, and boosts output.

5. Scalability That Traditional Systems Cannot Match

Expanding a traditional automated line often means rewiring, reprogramming, and multiple days of downtime. IIoT grows with your business. Need a new sensor? Add it. Want to track energy cost? Enable a module. Need remote monitoring? Activate dashboards. Scaling becomes faster, cheaper, and future-ready.

FAQs

Q1. Is IIoT replacing automation?

No. IIoT enhances automation by adding intelligence, connectivity, and real-time learning.

Q2. Does every factory need IIoT?

Factories looking for less downtime, better quality, and higher efficiency benefit the most.

Q3. Is IIoT costly to set up?

It depends on the scope, but long-term savings in maintenance and efficiency are significantly higher.

Conclusion

Traditional automation made industries faster.

But IIoT is making them smart — with real-time visibility, adaptive processes, predictive maintenance, and seamless connectivity. Factories that move beyond traditional setups and embrace IIoT aren’t just modernizing — they’re becoming future-proof.

Ready to unlock the power of IIoT for your operations? Reach out to us!