Machine downtime doesn’t just stop production—it stops revenue, disrupts schedules, and damages customer trust. In competitive manufacturing environments, even a few hours of unexpected equipment failure can mean the difference between profit and loss. The traditional approach to maintenance has always been reactive: wait for something to break, then fix it. Or preventive: service equipment on fixed schedules, whether it needs attention or not. Both methods are expensive, inefficient, and leave too much to chance. Industrial Internet of Things (IIoT) is rewriting the rules entirely.

The Real Cost of Unexpected Failures:

When a critical production line stops unexpectedly, the visible costs are obvious—lost production hours, emergency repair expenses, rush-ordered replacement parts at premium prices. But the hidden costs run deeper: delayed customer orders, overtime wages, compromised product quality, and increased safety risks. A single unplanned shutdown can cost lakhs in a matter of hours. Multiply that across multiple incidents per year, and the financial impact becomes staggering.

How IIoT Changes the Maintenance Game?

IIoT-driven predictive maintenance flips the script from reactive firefighting to proactive planning. Instead of guessing when equipment needs service, you know exactly what’s happening inside every critical asset—in real time. Continuous Health Monitoring: Sensors embedded in motors, pumps, and conveyors track vital performance indicators around the clock—temperature, vibration, pressure, electrical current, and cycle counts.

Explore our industrial hardware solutions to enable real-time monitoring.

Pattern Recognition:

Advanced analytics platforms compare current performance against historical baselines and known failure patterns. A bearing showing early wear or a motor drawing excess current triggers early warnings weeks before actual failure. These insights integrate seamlessly with existing SCADA systems and manufacturing platforms.

Learn more about OT software and data historian integration

Smart Action Plans: When potential issues are identified, the system provides specific guidance: which component is at risk, recommended maintenance actions, and optimal timing for intervention.

Real-World Impact

Consider an automotive parts manufacturer experiencing 8-10 unplanned stoppages monthly. After deploying IIoT predictive maintenance, their system flagged a hydraulic pump showing abnormal pressure fluctuations—three weeks before failure. Maintenance scheduled a replacement during a planned weekend shutdown, costing ₹25,000. Without that early warning, the pump would have failed mid-shift, halting production for 6+ hours. Cost: ₹3+ lakhs in lost production plus emergency repairs. Across a year, their unplanned downtime dropped by 65% and maintenance costs fell by 40%.

Getting Started

Successful implementation doesn’t require replacing existing infrastructure—modern IIoT solutions layer intelligence onto current systems.

Discover how turnkey IIoT solutions can enhance your factory operations.

- Focus on Critical Assets: Start with production bottlenecks and high-value equipment where failure creates the biggest impact.

- Integrate Seamlessly: Work with existing PLCs and control networks, extracting data without disrupting operations.

- Build the Right Workflows: Ensure maintenance teams have clear processes for responding to alerts and scheduling interventions.

Check our engineering consulting and training services.

Beyond Downtime

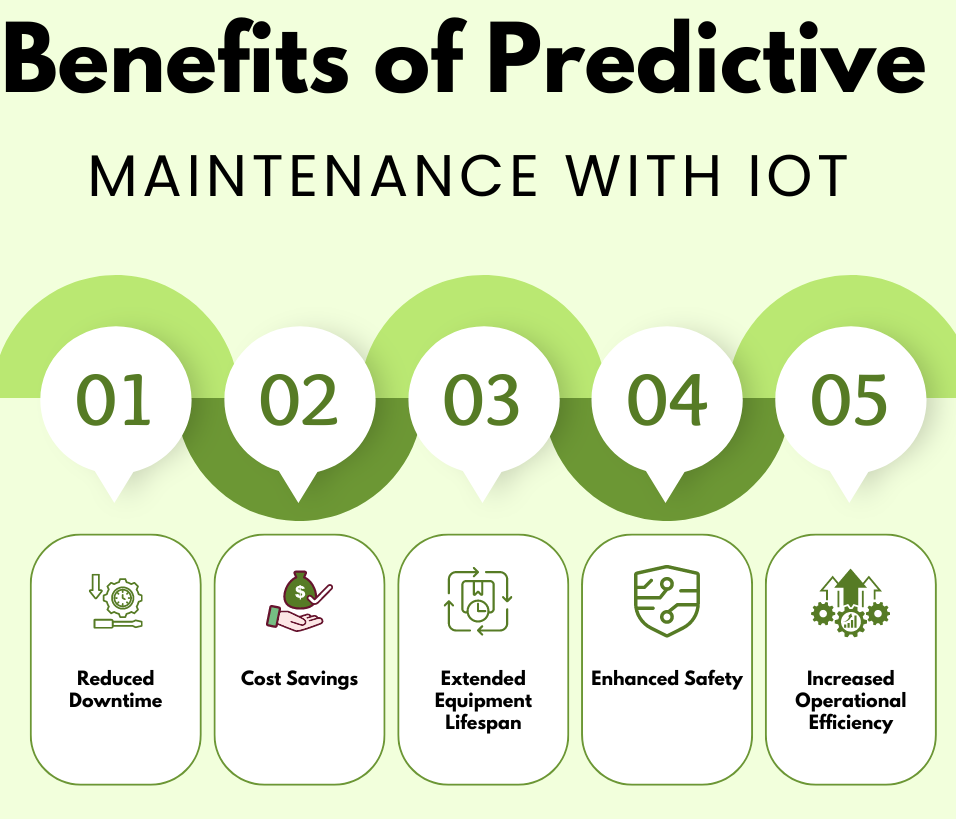

Predictive maintenance delivers additional advantages: optimised spare parts inventory, extended equipment lifespan, improved energy efficiency, and consistent product quality. Equipment operating in optimal condition lasts longer and performs better.

The Competitive Edge

Manufacturing competitiveness increasingly depends on operational reliability. Companies that minimise downtime and optimise maintenance spending have clear advantages over those still relying on reactive approaches. Your equipment is generating valuable data right now. The only question is whether you’re using it to prevent problems—or waiting for the next expensive breakdown.

Ready to reduce downtime and transform your maintenance strategy?

Connect with our industrial automation specialists.