Data without direction is just noise. Every factory generates massive amounts of operational data, but the real question is: Are you tracking the metrics that actually matter?

IIoT systems transform raw production data into actionable intelligence—but only if you’re measuring the right Key Performance Indicators (KPIs). The difference between factories that thrive and those that struggle often comes down to knowing which numbers to watch and how to respond when they shift.

Why Traditional Tracking Falls Short?

Manual data collection and spreadsheet-based reporting create two critical problems: they’re slow, and they’re incomplete. By the time you compile yesterday’s production numbers, identify issues, and plan responses, you’ve already lost valuable time and output. IIoT systems eliminate this lag. Sensors, connected equipment, and real-time analytics platforms deliver instant visibility into every aspect of factory performance.

Discover how OT software and data historian solutions provide real-time insights → LINK: https://devanta.tech/ot-software-implementation-data-historian/

The Essential KPIs for Smart Factories

Equipment Uptime and Availability –

Your production capacity means nothing if machines aren’t running. Equipment uptime measures the percentage of scheduled time that machinery operates productively. IIoT sensors track machine status continuously, instantly flagging when equipment goes offline and identifying patterns that predict future failures. A packaging line running at 85% uptime might seem acceptable until you calculate the cost: 15% downtime on a line producing ₹10 lakhs daily means ₹1.5 lakhs lost every single day. IIoT systems help push uptime into the 95%+ range where world-class manufacturers operate.

Production Throughput and Cycle Time –

How many units are you producing per hour, shift, or day? More importantly, how does actual output compare to theoretical capacity? IIoT systems track production counts in real time, measuring cycle times for each operation and identifying bottlenecks instantly. When a workstation’s cycle time increases from 45 seconds to 52 seconds, traditional methods might not notice for days. IIoT alerts trigger immediately, allowing quick intervention before the slowdown cascades through the entire production line.

Quality and First-Pass Yield –

Producing fast means nothing if you’re making defects. First-pass yield measures the percentage of products manufactured the first time, without rework or scrap. Connected quality inspection systems and inline sensors detect defects in real time, correlating quality issues with specific machines, operators, shifts, or material batches.

Explore our industrial hardware solutions for real-time quality monitoring → LINK: https://devanta.tech/industrial-hardware-sales-installation/

A 2% improvement in first-pass yield might sound modest, but on a line producing 10,000 units daily, that’s 200 fewer defects—translating to significant savings in materials, labour, and customer satisfaction.

Energy Consumption Per Unit –

Energy costs represent a major expense in manufacturing, yet many facilities have limited visibility into where power actually goes. IIoT-enabled energy monitoring tracks consumption at the machine level, revealing which equipment drives costs and when usage spikes occur. One electronics manufacturer discovered their injection moulding machines consumed 30% more energy during startup cycles. By optimising startup sequences based on IIoT data, they reduced monthly energy costs by ₹2+ lakhs without changing production volume.

Overall Equipment Effectiveness (OEE)

OEE combines availability, performance, and quality into a single metric that reveals true productive capacity. It answers the question: “What percentage of manufacturing time is truly productive?”

World-class manufacturers achieve OEE scores above 85%. Most factories operate between 40-60%. IIoT systems calculate OEE automatically and continuously, breaking down the three components to show exactly where losses occur—whether from downtime, speed losses, or quality defects.

Learn how turnkey IIoT solutions improve OEE → LINK: https://devanta.tech/turnkey-automation-iiot-solutions/

Maintenance Response Time –

When equipment issues arise, how quickly does your team respond and resolve them? IIoT systems timestamp every alert, maintenance action, and resolution, measuring mean time to repair (MTTR) and mean time between failures (MTBF).

Reducing MTTR from 90 minutes to 45 minutes doubles your ability to recover from issues quickly. IIoT-driven predictive maintenance takes this further by preventing many failures entirely.

Turning Metrics Into Action –

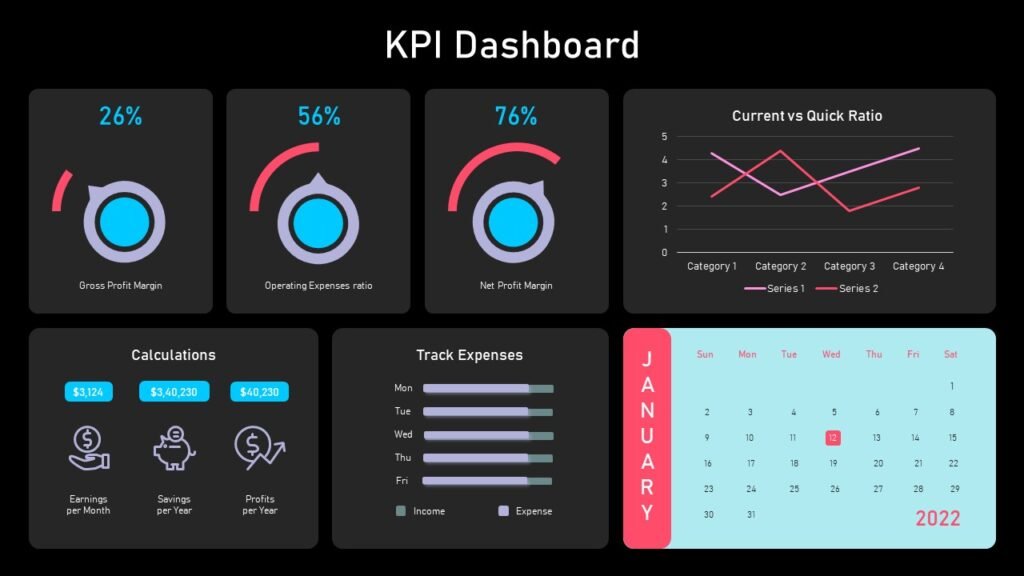

Tracking KPIs is pointless without action. The power of IIoT isn’t just measurement—it’s the ability to respond immediately when metrics deviate from targets. Real-Time Dashboards: Display current performance on shop floor screens where operators and supervisors can see it instantly. When throughput drops or quality issues spike, teams know immediately and can investigate before problems escalate.

- Automated Alerts: Configure thresholds that trigger notifications when KPIs move outside acceptable ranges. A sudden drop in equipment efficiency or spike in energy consumption generates instant alerts to the right people.

See our consulting and training services to set up automated KPI alerts → LINK: https://devanta.tech/engineering-consulting-training/

- Trend Analysis: Historical data reveals patterns invisible in daily operations. Seasonal variations, shift-based performance differences, or gradual equipment degradation become clear when you analyse trends over weeks and months.

Getting Started

You don’t need to track everything at once. Start with the KPIs that directly impact your biggest challenges—whether that’s downtime, quality issues, or production capacity constraints. Modern IIoT platforms integrate with existing equipment and control systems, extracting data without disrupting operations. As you build confidence and see results, expand monitoring to additional metrics and production areas. The factories winning in today’s competitive environment aren’t guessing—they’re measuring, analysing, and improving continuously.

Ready to gain real-time visibility into your factory performance?

Connect with our IIoT specialists to track the KPIs that matter most.