IIoT applications in plastic injection molding are transforming how manufacturers achieve real-time visibility on the shop floor. Plastic injection molding relies on speed, precision, and consistency, where even small changes in temperature, pressure, or cycle time can impact product quality and production efficiency. Traditionally, manufacturers depended on manual checks and post-production reports, often identifying issues only after waste and downtime occurred. IIoT changes this approach by delivering live production insights while machines are running.

Industrial Internet of Things (IIoT) changes this approach by bringing real-time visibility into injection molding operations.

Understanding Real-Time Visibility with IIoT Applications in Plastic Injection Molding

Real-time visibility means knowing exactly what is happening on your machines while production is running. IIoT-enabled sensors collect data continuously and display it on easy-to-read dashboards. Instead of assumptions or delayed reports, teams work with live information.

See how shop-floor data is captured and visualized using our OT Software Implementation & Data Historian Solutions.

Key IIoT Applications in Plastic Injection Molding

Real-Time Machine Status Tracking Using IIoT in Plastic Injection Molding

IIoT systems show whether a machine is running, idle, or stopped at any moment. This allows supervisors to identify bottlenecks instantly and take action without waiting for shift-end updates.

Discover how connected machines are enabled through our turnkey automation and IIoT Solutions.

Live Monitoring of Process Parameters

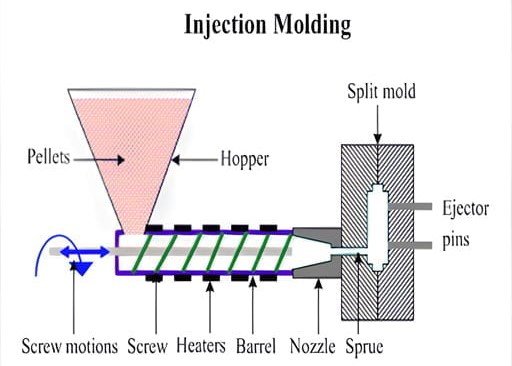

Injection molding requires stable process conditions. IIoT continuously tracks parameters such as barrel temperature, injection pressure, mold temperature, and cycle time. Any deviation is visible immediately, helping operators correct issues before defects occur.

Discover how reliable field devices and controllers support accurate data capture via our Industrial Hardware Sales and Installation services.

Downtime Visibility and Analysis

Instead of manually recording downtime, IIoT automatically logs stoppages and their duration. Over time, this data reveals patterns—frequent stops, long changeovers, or recurring faults—making improvement efforts more focused and effective.

Understand how downtime insights are turned into action using our Engineering, Consulting & Training Services.

Quality Insights During Production

Quality problems often start with small process variations. IIoT highlights these changes early, allowing teams to adjust settings before producing defective parts. This reduces scrap, rework, and customer complaints.

See how data-driven quality control is applied in our Manufacturing & Discrete Solutions.

Energy and Resource Awareness

Injection molding consumes significant energy. IIoT platforms track real-time power usage per machine or process, helping manufacturers identify inefficiencies and control operational costs.

Industry-Specific Relevance

Plastic injection molding plays a critical role across multiple industries, from precision automotive parts to high-speed packaging environments.

Is IIoT Suitable for Beginners?

Modern IIoT solutions are designed for simplicity. They integrate with both legacy and new machines, and dashboards are visual and intuitive. Even teams with limited digital experience can start benefiting from real-time insights quickly.

Our Engineering, Consulting & Training Services help teams adopt IIoT confidently and effectively.

Moving from Visibility to Smarter Operations

Real-time visibility is the foundation of smart manufacturing. Once data is visible, it becomes actionable. Over time, this leads to better maintenance planning, higher equipment utilization, and more predictable production outcomes.

Ready to bring real-time visibility to your plastic injection molding operations? Visit our Contact page to connect with our experts.

Frequently Asked Questions (FAQs)

1. What is IIoT in plastic injection molding?

IIoT connects molding machines, sensors, and software to collect and analyze production data in real time, improving visibility and control.

2. Can IIoT work with older injection molding machines?

Yes. Most IIoT solutions can integrate with legacy machines using external sensors and gateways.

3. How does real-time visibility reduce scrap and defects?

By detecting process deviations early, operators can correct issues before defective parts are produced.

4. Is IIoT difficult to use for shop-floor teams?

No. Modern IIoT platforms use visual dashboards that are easy to understand, even for beginners.

5. What is the first step to implementing IIoT in injection molding?

The first step is to assess machine connectivity and define which production parameters require real-time monitoring.