In many Indian manufacturing plants, energy is treated as a fixed cost—something unavoidable and difficult to control. Machines keep running, electricity bills keep rising, and the only time energy gets attention is when costs spike. The real issue is not energy consumption itself, but lack of visibility.

An Energy Monitoring System (EMS) changes this approach completely. It turns energy from an expense into a measurable, manageable parameter. For manufacturing plants in India, this shift is becoming essential—not optional.

Understanding Energy Monitoring in a Manufacturing Environment

An Energy Monitoring System tracks how much energy is consumed across machines, production lines, and utilities in real time. Instead of relying on monthly bills or manual logs, plant teams can see where energy is used, when it is wasted, and how it impacts production.

Unlike traditional audits that offer a one-time view, an EMS provides continuous insights. This allows manufacturers to detect abnormal consumption early and take corrective action before energy losses escalate.

Why Energy Monitoring Matters More in India

Manufacturing plants in India operate under challenging energy conditions—variable tariffs, peak demand charges, and increasing pressure to improve efficiency. Without accurate monitoring, energy costs quietly reduce margins and affect competitiveness.

An energy monitoring system helps Indian manufacturers:

- Gain real-time visibility into energy usage

- Identify energy-intensive machines and identify idle consumption

- Control peak demand and reduce penalties

- Improve efficiency without compromising output

- Support sustainability and compliance initiatives

Industries such as Automotive & Auto Components, Electrical & Electronics, Packaging, Machinery Manufacturing, and Process & Chemicals are increasingly adopting energy monitoring as a strategic necessity.

Key Value Delivered by an Energy Monitoring System

The real value of an energy monitoring system is not data—it is actionable insight.

- Cost Control

Detect wastage, leaks, and inefficiencies that directly impact energy bills. - Operational Efficiency

Align energy usage with production schedules and actual demand. - Informed Decision-Making

Replace assumptions with reliable, real-time data. - Peak Load Optimization

Monitor demand patterns and avoid unnecessary peak charges. - Long-Term Sustainability

Track energy performance and support energy efficiency goals.

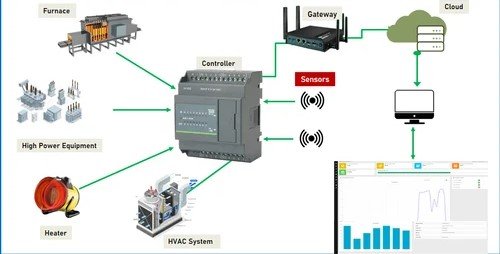

How an Energy Monitoring System Works in Practice

An EMS collects energy data from machines, panels, and utilities and converts it into visual dashboards and reports. Supervisors and management can:

- Monitor live energy consumption

- Compare energy usage across shifts or lines

- Analyze historical trends

- Receive alerts for abnormal usage

This level of transparency allows manufacturing teams to respond quickly and improve continuously.

Devanta Tech’s Approach to Energy Monitoring

At Devanta Tech, we believe energy monitoring should be practical, scalable, and aligned with plant operations—not complex or over-engineered.

Our Implementation Process:

- Energy Assessment & Consulting

Understanding your plant’s energy flow and identifying improvement opportunities. - Energy Monitoring System Deployment

Customized dashboards designed around your production and energy KPIs. - OT Software Implementation & Data Historian

Centralized, reliable data storage for analysis and reporting. - Industrial Hardware Sales & Installation

Ensuring a stable and accurate data capture infrastructure. - Engineering, Consulting & Training

Enabling teams to interpret insights and drive optimization.

Our solutions are built for Manufacturing & Discrete, Automotive, Packaging, and other energy-intensive industries across India.

From Energy Spend to Energy Strategy

Energy efficiency is no longer just about saving costs—it’s about building resilient and competitive manufacturing operations. With the right energy monitoring system, manufacturers gain control, clarity, and confidence in their energy decisions.

Talk to Devanta Tech to implement an energy monitoring system designed for Indian manufacturing plants.

Frequently asked questions (FAQs)

1. What is the difference between energy monitoring and energy management?

Energy monitoring focuses on real-time visibility, while energy management uses that data to drive long-term optimization.

2. Can energy monitoring affect production output?

No. It improves efficiency without disrupting production.

3. Is an energy monitoring system scalable?

Yes. It can start small and expand across machines, lines, and plants.