India’s manufacturing sector is at a decisive stage of growth. Increasing global competition, rising operational costs, and the demand for faster delivery are prompting manufacturers to reassess their traditional working methods. In this changing environment, digital transformation in manufacturing has become a key driver of efficiency, visibility, and long-term competitiveness. Concepts such as Smart Factory India and Industry 4.0 India are no longer futuristic ideas—they are actively shaping today’s factories.

For Indian manufacturers, digital transformation is less about replacing machines and more about connecting systems, improving decision-making, and gaining control over daily operations.

What Digital Transformation Means for Indian Manufacturers

Digital transformation in manufacturing refers to the use of digital technologies to monitor, analyze, and improve shop-floor operations. In the Indian context, this transformation focuses on practicality—working with existing infrastructure while gradually moving toward a smart factory India model.

Many factories still depend on manual reports and delayed data, making it difficult to identify losses or take timely action. Digital systems bridge this gap by converting real-time machine and production data into actionable insights. This forms the foundation for Industry 4.0 India, where data-driven operations enable consistent improvement.

Why Smart Factory Adoption Is Growing in India

The idea of a smart factory in India is gaining momentum as manufacturers look for better visibility without increasing complexity. A smart factory connects machines, operators, and systems to enable real-time monitoring and faster decision-making.

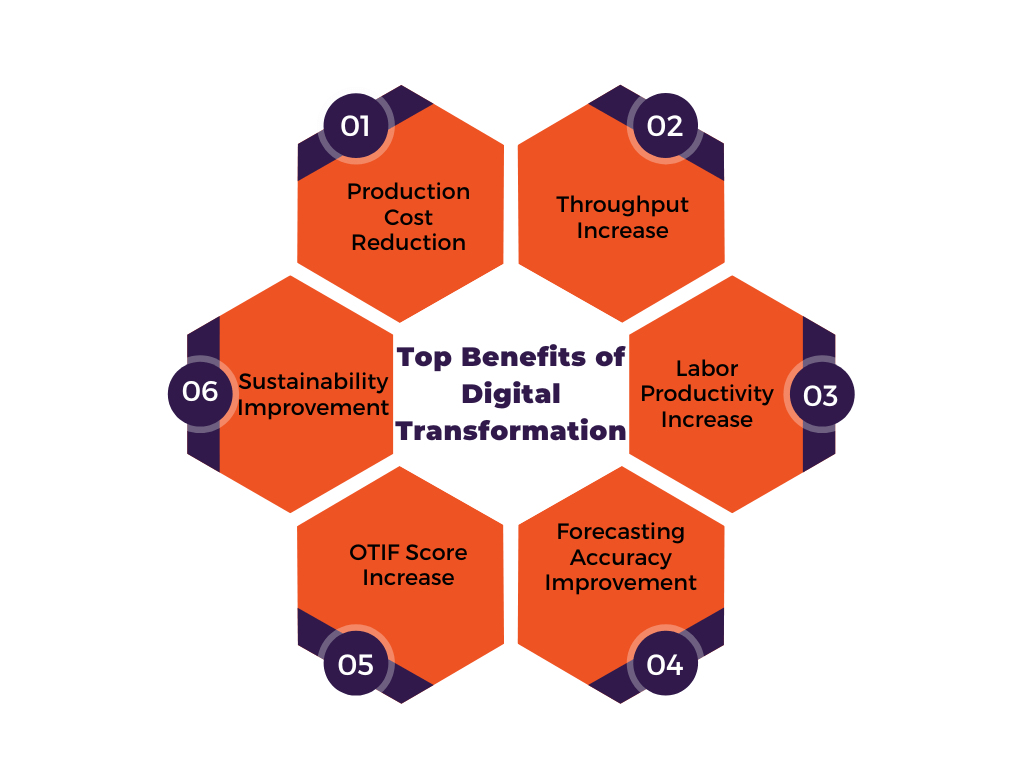

Through digital transformation in manufacturing, Indian factories can:

- Reduce unplanned downtime

- Improve machine utilization

- Optimize energy and resource usage

- Maintain consistent quality

These benefits are especially important in cost-sensitive environments and directly support the goals of Industry 4.0 India.

Industry 4.0 India: A Practical, Phased Approach

Industry 4.0 India is often associated with advanced automation and analytics, but successful implementation depends on a phased approach. Indian manufacturers benefit most by starting with visibility, followed by control and optimization.

Rather than adopting all technologies at once, a step-by-step strategy ensures that digital transformation in manufacturing delivers measurable value at every stage. This practical approach allows manufacturers to build toward a smart factory India model without operational disruption.

Devanta Tech’s Approach to Digital Transformation

At Devanta Tech, we believe digital transformation in manufacturing should be realistic, scalable, and aligned with shop-floor realities.

We start by understanding business goals, production challenges, and improvement opportunities. This phase is strengthened through Devanta Tech’s engineering, consulting, and training services, helping manufacturers define a clear digital roadmap aligned with Industry 4.0 India objectives.

Start with the right roadmap for your digital journey

Engineering, Consulting & Training

Accurate and reliable data is essential for any smart factory India initiative. Devanta Tech supports industrial hardware sales and installation, enabling seamless data capture from both legacy and modern machines.

Build a strong data foundation at the shop-floor level

Industrial Hardware Sales & Installation

Once data is available, we implement OT software platforms and data historian solutions that convert raw operational data into dashboards and reports for daily decision-making and long-term analysis.

Turn operational data into meaningful insights

OT Software Implementation & Data Historian

For manufacturers looking for end-to-end execution, Devanta Tech delivers turnkey automation and IIoT solutions that integrate machines, systems, and people into a connected smart factory ecosystem.

Move closer to a connected and intelligent factory

Turnkey Automation & IIoT Solutions

This structured approach ensures digital transformation in manufacturing remains sustainable and aligned with evolving business needs.

Industries Driving Digital Transformation in India

Across India, multiple sectors are actively adopting digital transformation in manufacturing. Automotive and auto component manufacturers focus on productivity and downtime reduction. Discrete and machinery manufacturers aim to improve utilization and planning efficiency. Electrical, electronics, packaging, and process industries leverage digital tools for quality, traceability, and process stability.

Devanta Tech adapts Industry 4.0 India solutions to suit the unique requirements of each sector

Conclusion

As India’s manufacturing ecosystem evolves, digital transformation in manufacturing is becoming the foundation for smarter, more resilient operations. By adopting a phased and practical approach to smart factory India initiatives and aligning them with Industry 4.0 India, manufacturers can unlock real operational value without disrupting existing systems.

Devanta Tech partners with Indian manufacturers throughout this journey—helping turn operational data into informed decisions and future-ready manufacturing operations.

Take the next step toward smarter manufacturing:

Contact us

Frequently asked questions (FAQs)

1. Is digital transformation in manufacturing suitable for small Indian factories?

Yes. With phased implementation, even small and mid-sized manufacturers can begin their digital journey without heavy investment.

2. What is the first step toward building a smart factory in India?

Gaining real-time visibility into machines and production is the first and most critical step.

3. How does Industry 4.0 India benefit traditional factories?

Industry 4.0 India helps traditional factories reduce losses, improve efficiency, and make data-driven decisions using existing infrastructure.