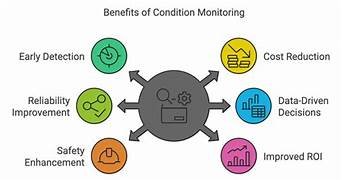

In modern manufacturing, equipment reliability directly impacts productivity, quality, and profitability. Yet many plants still struggle with unexpected breakdowns due to limited visibility into machine health. This is where Devanta Tech’s condition monitoring in manufacturing plays a critical role.

At Devanta Tech, we help manufacturers implement intelligent condition monitoring systems that provide real-time insights into equipment performance. By combining a robust machine monitoring system with an enterprise-ready asset monitoring system, we enable organizations to move from reactive maintenance to data-driven, proactive operations.

Devanta Tech’s Approach to Condition Monitoring

Condition monitoring is not just about installing sensors—it is about building a connected ecosystem. Devanta Tech designs and deploys scalable condition monitoring systems tailored to your plant’s assets, processes, and business objectives.

Our solutions focus on:

- Continuous machine health visibility

- Early fault detection

- Reduced unplanned downtime

- Improved maintenance planning

With Devanta Tech, a machine monitoring system becomes a strategic tool that supports reliability, efficiency, and long-term operational excellence.

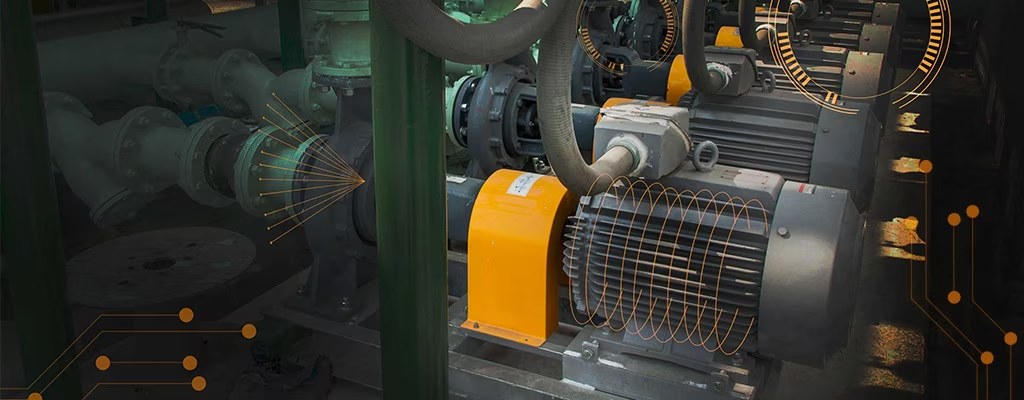

Sensors Used in Devanta Tech’s Condition Monitoring Solutions

Sensors are the foundation of every condition monitoring system we implement. Devanta Tech provides Industrial Hardware Sales & Installation with reliable, industrial-grade sensors selected based on asset criticality.

Common sensors used include:

- Vibration Sensors – Detect imbalance, bearing failure, and mechanical wear

- Temperature Sensors – Monitor motors, gearboxes, panels, and critical components

- Current & Power Sensors – Track electrical health and energy consumption

- Pressure & Flow Sensors – Ensure stable hydraulic and pneumatic operations

- Environmental Sensors – Monitor ambient conditions affecting equipment

All sensor data is integrated into a centralized machine monitoring system, which further feeds into a plant-wide asset monitoring system for complete visibility.

Use Cases Enabled by Devanta Tech

Devanta Tech’s condition monitoring solutions deliver measurable value across manufacturing operations:

- Predicting equipment failures before they impact production

- Reducing unplanned downtime through real-time alerts

- Optimizing maintenance schedules using actual asset condition

- Improving energy efficiency by identifying abnormal usage patterns

- Extending asset life through timely maintenance actions

By deploying a connected machine monitoring system, maintenance teams gain actionable insights instead of relying on assumptions. A unified asset monitoring system ensures consistent monitoring across machines, lines, and plants.

How Devanta Tech Implements Condition Monitoring

Devanta Tech follows a structured, proven process to implement condition monitoring in manufacturing:

- Asset & Process Assessment – Identify critical machines and failure risks

- Sensor Selection & Installation – Deploy reliable hardware for accurate data capture

- OT Software Implementation & Data Historian – Enable real-time and historical visibility

- Analytics, Dashboards & Alerts – Convert raw data into actionable insights

- Engineering, Consulting & Training – Build internal capability for long-term success

This approach ensures your condition monitoring system evolves into a scalable machine monitoring system and a centralized asset monitoring system aligned with business goals.

Why Choose Devanta Tech?

Devanta Tech is not just a solution provider—we are a long-term technology partner. Our expertise in Turnkey Automation & IIoT Solutions ensures seamless integration between hardware, OT systems, and analytics platforms.

We help manufacturers achieve:

- Higher equipment reliability

- Lower maintenance costs

- Better asset utilization

- Data-driven maintenance decisions

Explore our Industrial Hardware, OT Software, and IIoT solutions to see how Devanta Tech can transform your condition monitoring strategy.

Frequently asked questions (FAQs)

1. How does Devanta Tech’s condition monitoring system help manufacturers?

It provides real-time machine health insights, early fault detection, and centralized asset visibility to reduce downtime.

2. Can Devanta Tech’s machine monitoring system scale across plants?

Yes. Our solutions are scalable and can be expanded from a single machine to multi-plant asset monitoring systems.

3. Does Devanta Tech provide support after implementation?

Absolutely. We offer engineering support, consulting, and training to ensure long-term success.