Unplanned equipment failures are one of the biggest cost drivers in manufacturing today. Downtime impacts production schedules, product quality, energy efficiency, and customer commitments. To manage this risk, manufacturers typically rely on two maintenance strategies—preventive maintenance and predictive maintenance.

But as factories move toward digitalization and smart operations, the real question is no longer whether maintenance is required, but which approach delivers better long-term value and operational control.

Understanding Preventive Maintenance

Preventive maintenance is a traditional, schedule-based approach where machines are serviced at fixed time intervals or after a defined number of operating hours. This method helps reduce sudden breakdowns and ensures basic equipment reliability.

However, preventive maintenance does not consider the actual condition of the asset. Machines may be serviced even when no issue exists, leading to unnecessary downtime and higher maintenance costs. In fast-paced production environments, this approach often results in inefficiencies and limited visibility.

What Is Predictive Maintenance?

Predictive maintenance focuses on real-time condition monitoring to identify potential failures before they occur. Instead of relying on assumptions, manufacturers use data-driven insights to make informed maintenance decisions.

Predictive maintenance in manufacturing uses live data from sensors monitoring parameters such as vibration, temperature, pressure, and energy consumption. When combined with analytics, this data enables early fault detection and accurate failure prediction.

With predictive maintenance using IIoT, machines become connected assets that continuously communicate their health status—allowing maintenance teams to act at the right time, not too early or too late.

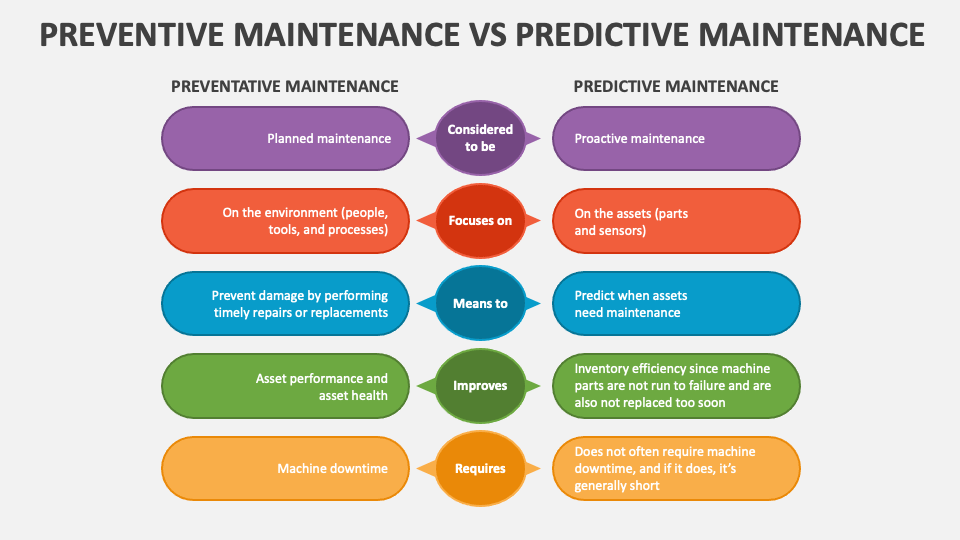

Predictive vs Preventive Maintenance: Key Differences

Preventive maintenance is time-based and reactive, while predictive maintenance is condition-based and proactive. Predictive strategies reduce unplanned downtime, extend equipment life, and improve overall equipment effectiveness.

More importantly, maintenance automation ensures that alerts, diagnostics, and responses happen automatically, reducing dependency on manual inspections and human intervention.

Why Predictive Maintenance Is the Smarter Choice

In modern factories, static maintenance schedules are no longer enough. Predictive maintenance in manufacturing enables organizations to:

- Minimize unexpected equipment failures

- Reduce maintenance and spare part costs

- Improve asset utilization

- Increase plant reliability

- Enhance energy efficiency

By leveraging predictive maintenance using IIoT and maintenance automation, manufacturers gain complete visibility across operations and move toward knowledgeable maintenance systems.

Devanta Tech’s Role in Enabling Predictive Maintenance

At Devanta Tech, we help manufacturers move beyond traditional maintenance approaches and adopt intelligent, data-driven strategies. Our solutions are designed to make predictive maintenance in manufacturing practical, scalable, and results-driven.

We enable predictive maintenance using IIoT by seamlessly integrating industrial hardware, OT systems, and advanced data historians. With built-in maintenance automation, our solutions provide real-time alerts, actionable insights, and performance visibility—helping teams prevent failures before they impact production.

How Devanta Tech Supports Your Maintenance Journey

We offer end-to-end solutions tailored to your operational needs:

Industrial Hardware Sales & Installation

Reliable sensors and industrial hardware for accurate condition monitoring.

OT Software Implementation & Data Historian

Centralized, real-time data visibility for smarter maintenance decisions.

Turnkey Automation & IIoT Solutions

End-to-end predictive maintenance using IIoT with scalable architecture.

Engineering, Consulting & Training

Build internal expertise and long-term maintenance excellence.

Industries We Serve

Devanta Tech delivers predictive maintenance in manufacturing across multiple sectors, including:

- Automotive & Auto Components

- Manufacturing & Discrete Industries

- Electrical & Electronics

- Machinery & Equipment Manufacturing

- Packaging Industry

- Process & Chemicals

Each solution is customized based on asset criticality, production complexity, and business objectives.

Ready to Transform Your Maintenance Strategy?

If your organization is still relying on reactive or time-based maintenance, it’s time to rethink your approach. Predictive maintenance using IIoT, supported by maintenance automation, can significantly improve reliability, efficiency, and profitability.

Contact Us Today to explore how Devanta Tech can help you implement a smarter, future-ready maintenance strategy tailored to your manufacturing operations.

Frequently asked questions (FAQs)

1. Is predictive maintenance suitable for all manufacturing plants?

Yes. Predictive maintenance can be scaled based on asset criticality and plant size.

2. Can predictive and preventive maintenance work together?

Absolutely. Many manufacturers use preventive maintenance for non-critical assets and predictive maintenance for critical equipment.

3. How long does it take to implement predictive maintenance?

Implementation timelines vary, but initial insights can often be achieved within weeks with the right IIoT and automation setup.