Unplanned equipment breakdowns are one of the biggest cost drivers in modern manufacturing. For many plants, especially in energy, food processing, and discrete manufacturing across Malta and Europe, a single breakdown doesn’t just stop a machine—it disrupts schedules, manpower, and customer commitments.

Traditional breakdown analysis depends heavily on manual logs, operator experience, and post-incident meetings. By the time a root cause is identified, the damage is already done. This is where Breakdown Analytics, powered by IIoT (Industrial Internet of Things), changes the game.

Instead of asking “What went wrong?” after a failure, IIoT systems answer “Why did this happen?” automatically—and in real time.

What Is Breakdown Analytics in IIoT?

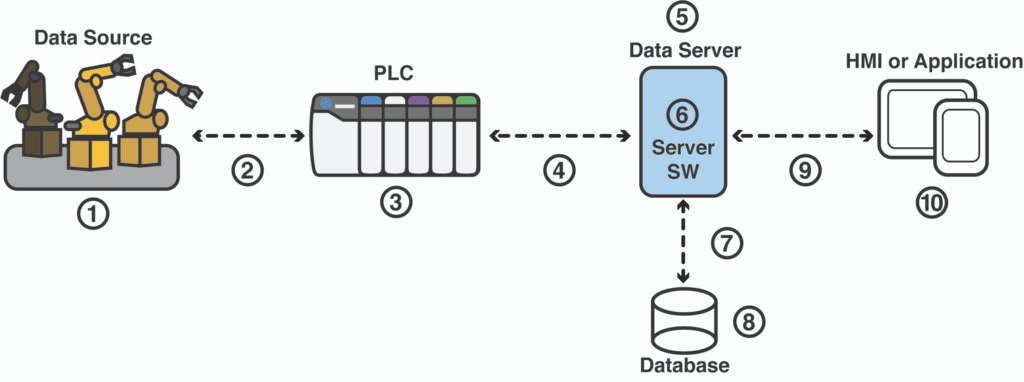

Breakdown analytics is the process of using live machine data, historical patterns, and contextual information to identify the exact causes of equipment failure. IIoT makes this possible by continuously collecting data from sensors, PLCs, drives, and control systems.

Unlike basic monitoring, IIoT doesn’t just show alarms. It connects multiple data points—temperature, vibration, load, pressure, cycle time, and operator actions—to reveal hidden failure patterns that humans often miss.

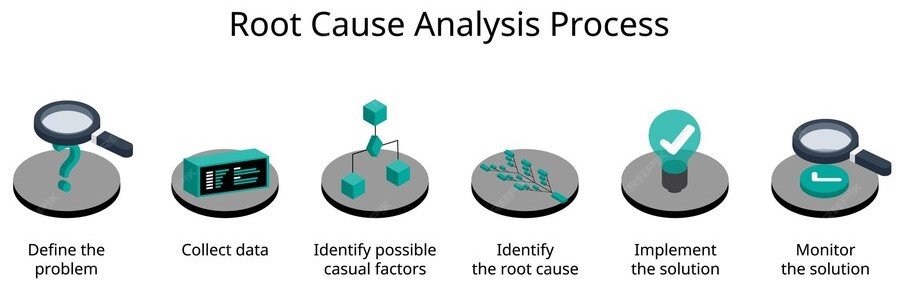

How IIoT Automatically Finds Root Causes

1. Continuous Multi-Source Data Capture

IIoT platforms gather data from machines, utilities, and production systems simultaneously. When a breakdown occurs, the system already has the full operational context—before, during, and after the event.

If your plant relies on industrial sensors and controllers, explore our Industrial Hardware Sales & Installation services to build a reliable data foundation.

2. Pattern Recognition & Correlation

Instead of isolated alarms, IIoT analytics correlates trends. For example:

- Repeated motor trips after temperature spikes

- Bearing failures linked to load fluctuations

- Downtime recurring during specific shifts or batches

These correlations highlight the true root cause, not just the symptom.

Learn how our OT Software & Data Historian Solutions turn raw machine data into actionable insights.

3. Automated Root Cause Identification

Modern IIoT systems apply rules, logic models, and AI-assisted analytics to automatically tag breakdown reasons such as:

- Process instability

- Mechanical wear

- Electrical anomalies

- Human or operational errors

This removes guesswork and speeds up corrective action.

4. Context-Aware Alerts (Not Alarm Floods)

Instead of overwhelming teams with alerts, IIoT prioritizes root-cause-based notifications. Maintenance teams know what failed, why it failed, and what to fix first—before restarting production.

Our Industrial Automation & IIoT Solutions are designed to reduce downtime, not increase dashboards.

Why This Matters for Plants in Malta

With limited space, skilled labor constraints, and high energy costs, Maltese industries cannot afford reactive maintenance. Breakdown analytics enables:

- Faster recovery times

- Lower maintenance costs

- Higher equipment availability

- Better compliance and audit readiness

More importantly, it builds a predictive culture, where failures are understood—not repeated.

From Data to Decisions: The Real Business Impact

Companies using IIoT-based breakdown analytics often see:

- 20–40% reduction in unplanned downtime

- Clear accountability between operations and maintenance

- Improved asset lifespan and ROI

This is not about replacing people—it’s about empowering teams with facts instead of assumptions.

Final Thoughts

Breakdown analytics is no longer a luxury—it’s a necessity for competitive manufacturing. IIoT enables machines to explain why they fail, automatically and accurately, so businesses can act with confidence.

If you’re looking to move beyond reactive maintenance and build a smarter, more resilient plant in Malta, the right IIoT strategy makes all the difference.

Get in touch via our Contact Us page to discuss how breakdown analytics can be implemented in your facility.