Unexpected machine failures can disrupt production, increase repair expenses, and hurt customer trust. In many industries, a single breakdown can stop operations for hours or even days. Traditional maintenance methods—whether reactive or based on fixed schedules—often fail to prevent these issues. This is where Predictive Maintenance powered by IIoT (Industrial Internet of Things) has become essential.

Predictive maintenance utilizes real-time data and smart sensors to identify early signs of machine problems before they escalate into costly failures. The result? Lower maintenance costs, reduced downtime, and longer equipment life.

Why Old Maintenance Methods Don’t Work Anymore

Reactive Maintenance

Machines are repaired only after they fail. This causes sudden breakdowns, production loss, and high emergency repair costs.

Preventive Maintenance

Machines are serviced on a fixed routine (monthly, quarterly, etc.).

But this still creates problems:

- Parts may be replaced even when they’re still working perfectly

- Hidden failures between routines go unnoticed

- Time and resources are wasted

Both methods rely on assumptions—not real equipment data.

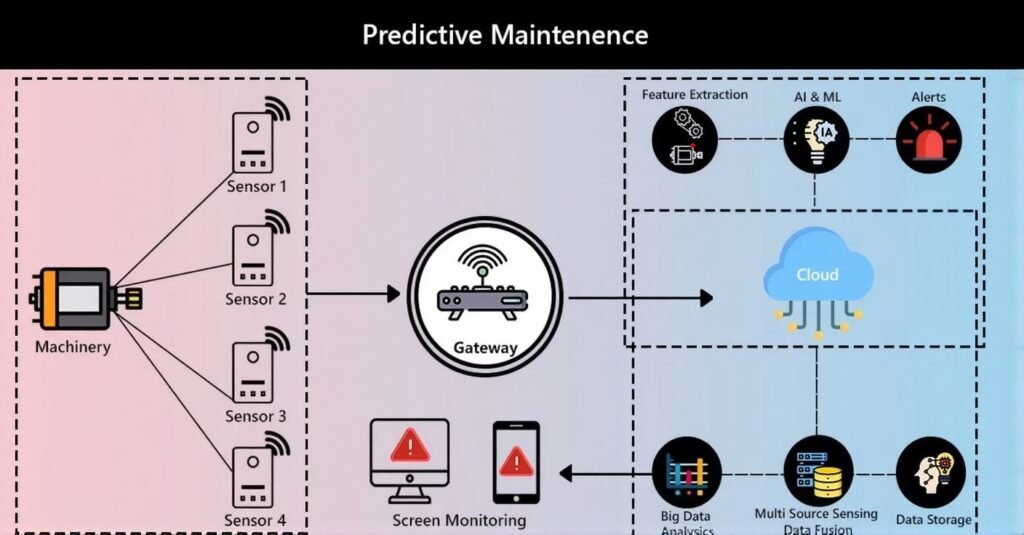

How Predictive Maintenance Works

Predictive Maintenance uses IIoT sensors to continuously monitor machine health. These sensors track critical parameters like:

- Temperature

- Vibration

- Pressure

- Energy consumption

- Motor load

- Noise levels

Whenever the system detects unusual patterns, it sends instant alerts to the maintenance team. This gives enough time to fix the issue before it becomes a breakdown.

To implement this kind of monitoring, industries need reliable and robust industrial hardware.

Explore our industrial hardware solutions.

How Predictive Maintenance Saves Cost, Time & Breakdowns

1. Lower Maintenance Costs

By servicing only when required, you avoid unnecessary part replacements. Many companies experience 20–30% cost savings in maintenance operations.

2. Reduced Downtime

Predictive alerts prevent sudden failures. Maintenance becomes planned, not forced—keeping production smooth and uninterrupted.

3. Extended Equipment Life

Machines that operate within safe limits last much longer. Sensors ensure early detection of any stress or imbalance, reducing wear and tear.

4. Faster Issue Diagnosis

With real-time dashboards and trend data, technicians instantly know where the problem is—saving hours of troubleshooting.

5. Enhanced Safety

Predictive systems prevent dangerous failures that could put workers or equipment at risk.

Industries Benefiting the Most

Predictive Maintenance is widely used in:

- Manufacturing

- Automotive

- Food & Beverage

- Energy & Utilities

- Pharmaceuticals

- Oil & Gas

Any industry with heavy machinery can dramatically reduce breakdowns using IIoT.

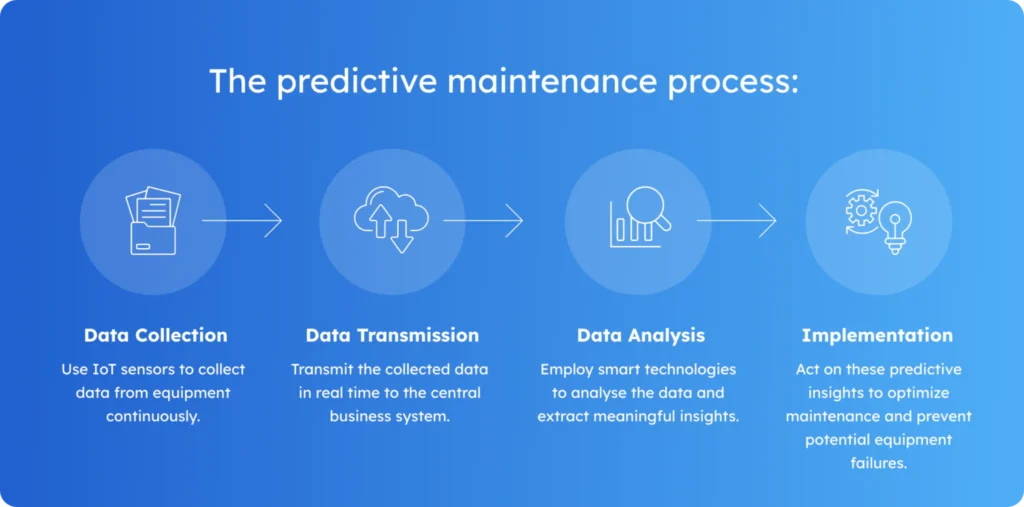

How to Get Started with Predictive Maintenance

Implementing Predictive Maintenance does not require a complete digital overhaul. You can begin in small, practical steps:

- Identify critical machines where failures are most costly.

- Install IIoT sensors to track key performance indicators.

- Connect sensors to monitoring and analytics software.

- Set thresholds and receive alerts for abnormal readings.

- Take preventive action before breakdowns occur.

- Scale the same system across more equipment over time.

Explore more automation & IIoT services on our website.

Predictive Maintenance is the Future

As industries move toward smarter and more efficient operations, Predictive Maintenance is becoming a must-have strategy. It reduces costs, eliminates guesswork, improves reliability, and ensures machines perform at their best. With IIoT, companies can stop reacting to breakdowns—and start preventing them.

To discuss predictive maintenance for your facility, contact our team.