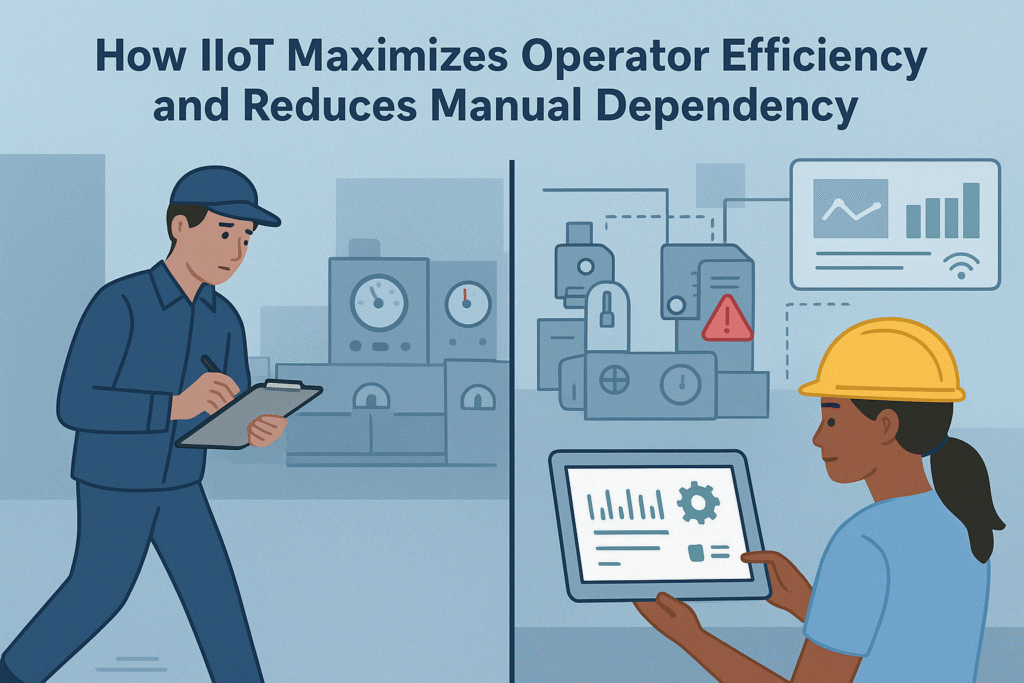

Picture operator Raj walking 12 kilometres per shift with a clipboard, checking 15 machines hourly, writing readings in logbooks. Now meet Priya—she monitors 20 machines from her tablet, gets instant alerts, and solves real problems instead of collecting data. The difference? Smart, connected systems that work for operators, not against them.

The Manual Work Problem

Traditional factories waste operator talent. Workers spend 40-50% of their time collecting data—walking between machines, reading gauges, writing numbers. It’s repetitive, tiring, and prone to errors. By the time someone manually identifies a problem, damage has already been done. A motor overheated for hours. 500 defective products were made. Quality parameters drifted unnoticed. Manual methods also create inconsistent data. One operator’s “normal noise” is another’s “concerning vibration.” Human judgment varies, and errors creep in.

→ Discover our Turnkey Automation & IIoT Solutions

How Connected Systems Transform Operations:

- Automatic Data Collection: Industrial sensors and PLCs capture temperature, pressure, speed, and vibration every second. Zero time spent writing readings. Data flows automatically into central systems.

- Instant Alerts: When parameters go out of range, operators get immediate notifications on mobile devices or HMI screens. They respond to problems, not search for them.

- Remote Monitoring: SCADA systems and data platforms show the real-time status of entire production lines from one location. No physical visits needed for routine checks.

- Predictive Maintenance: Smart systems analyse patterns and predict service needs. Fix issues during planned downtime, not production emergencies. Prevent breakdowns before they happen.

→ Learn about our Industrial Hardware Sales & Installation

Real Benefits You’ll See:

- Time Savings: 3-4 hours saved per shift—30-40% more productive time

- Fewer Errors: Automated collection eliminates human mistakes in recording

- Faster Response: Issues addressed in minutes, downtime drops 25-40%

- Better Decisions: Real data replaces gut feelings and guesswork

- Improved Safety: Continuous monitoring prevents dangerous situations

- Higher Satisfaction: Operators focus on meaningful work, not tedious tasks

→ Explore our OT Software Implementation & Data Historian

Industry Results:

Automotive: Quality up 25%, workload down 35% Electronics: Compliance time from 4 hours to zero. Packaging: Accuracy reached 99.9% Machinery: 2.5 hours saved per shift. Process & Chemical: Safety incidents decreased significantly

Getting Started Practically

Step 1: Ask operators which manual tasks waste the most time. Start with their biggest frustration.

Step 2: Start small—one production line or one critical process. Prove value before expanding.

Step 3: Install industrial-grade sensors and controllers designed for harsh factory environments.

Step 4: Integrate with existing SCADA and control systems. No need to replace what’s working.

Step 5: Provide proper training and support so operators embrace new tools confidently.

Looking for expert guidance? Our Engineering, Consulting & Training team helps you implement automation successfully.

Addressing Common Concerns

“Our operators won’t like this.” Actually, they will. Nobody enjoys walking miles to write numbers. Frame it as “freeing you from boring tasks for interesting work.”

“Our equipment is too old.” Age doesn’t matter. Modern systems connect to equipment from any era through standard industrial protocols.

“What’s the investment?” Most factories see ROI within 12-18 months through reduced downtime, fewer errors, and better productivity.

Conclusion:

The future of manufacturing isn’t about replacing operators—it’s about empowering them. Smart automation eliminates tedious tasks, allowing your workforce to focus on solving problems and driving improvements. Every hour spent walking with clipboards is an hour not spent making your factory better. Automated sensors handle monitoring. Real-time platforms provide insights. Your operators transform from data collectors into decision-makers. Factories worldwide are making this shift. Those embracing automation thrive. Those clinging to manual methods fall behind. Your operators are your most valuable asset—stop wasting their potential on tasks technology handles better.

Ready to maximise operator efficiency? Contact us today to start your automation journey.

Frequently Asked Questions (FAQ’s)

- Will automation replace our operators?

A: No. It eliminates tedious tasks. Operators become problem-solvers, making their roles more valuable and skilled.

- What happens if systems fail?

A: Industrial platforms have built-in backups and redundancy. Manual methods remain available as a fallback.

- Do we need IT experts to manage this?

A: No. Operational teams can manage systems with proper training. We provide ongoing support.

- How quickly will we see results?

A: Immediate time savings when manual data collection stops. Most facilities see 20-30% efficiency gains within 6 months.

- Does this work with old equipment?

Yes. Modern sensors and controllers connect to equipment from any era using standard protocols