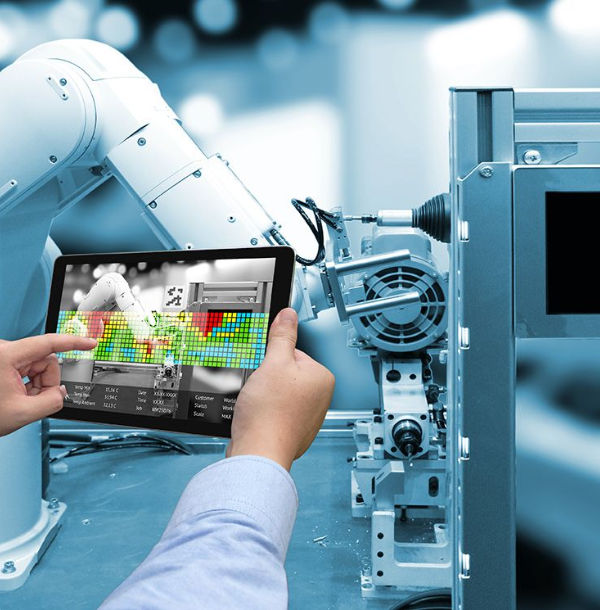

Machinery & Equipment Manufacturing

Real-time intelligence for smarter, safer, more reliable equipment.

Design, build, and service complex machinery faster with end-to-end visibility—from engineering and fabrication to final assembly and aftermarket service. We integrate IIoT, MES/SCADA, and AI/ML to improve first-pass yield, shorten changeovers, and reduce unplanned downtime across multi-variant, engineer-to-order (ETO) and configure-to-order (CTO) environments.

Real time Perfomance Report send

User Friendly SEO Dashboard

Local SEO & Business Integrations

Social Media Integration and Sharing

Key Industry Challenges

Machinery manufacturing challenges: managing ETO/CTO complexity, long lead times, and quality compliance.

ETO/CTO complexity

-

Frequent design changes and custom BOMs strain planning, production, and quality.

Frequent design changes and custom BOMs strain planning, production, and quality.

Long lead times & WIP

-

Complex multi-stage builds and tangled supplier dependencies severely delay delivery.

Complex multi-stage builds and tangled supplier dependencies severely delay delivery.

Quality & compliance

-

Tight tolerances, safety standards, and documentation burdens increase risk

Tight tolerances, safety standards, and documentation burdens increase risk

Our Solutions

IIoT, MES/SCADA, and AI/ML to raise OEE, shorten lead times, and deliver audit-ready quality and genealogy.

Strategic Outcomes

Business Impact

Quantifiable gains in efficiency, uptime, and quality—driven by automation, predictive insights, and connected operations.

- +15–30% OEE via real-time visibility, standardized workflows, and bottleneck removal.

- −20–40% unplanned downtime with predictive maintenance and condition monitoring.

- Fewer defects & rework through SPC, digital verification, and torque/parameter capture

- Shorter lead times with optimized scheduling, lower WIP, and faster changeovers.