Electrical & Electronics

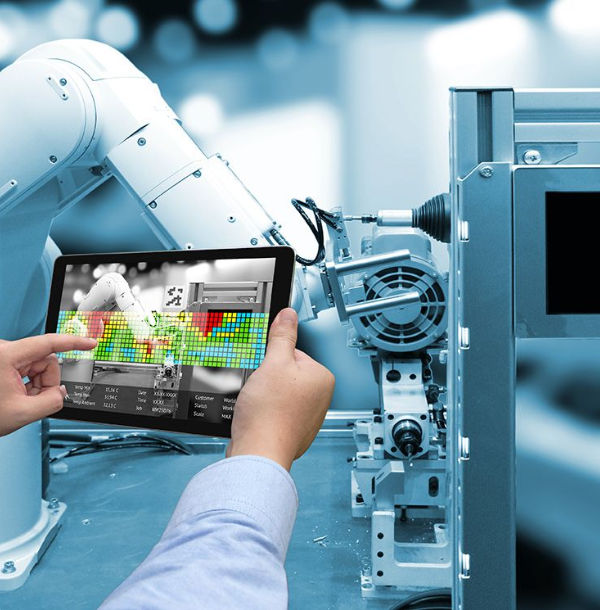

Intelligent Manufacturing for Electrical & Electronics

Accelerate product innovation and scale high-mix, high-volume production with connected manufacturing. We integrate IIoT, MES/SCADA, and AI/ML to boost first-pass yield, cut downtime, and ensure unit-level traceability. From PCB design and SMT placement to reflow, AOI, ICT/FCT, and final test, every step is monitored in real time. Standardized workflows, digital travelers, and predictive insights shorten changeovers, reduce scrap, and speed compliance, enabling faster launches and resilient, data-driven electronics operations worldwide.

Real time Perfomance Report send

User Friendly SEO Dashboard

Local SEO & Business Integrations

Social Media Integration and Sharing

Key Industry Challenges

Automotive manufacturing challenges: navigating complexity, compliance, and supply chain risk.

High-mix complexity & short lifecycles

-

Frequent NPI and changeovers increase risk of errors and delays.

Frequent NPI and changeovers increase risk of errors and delays.

Quality & compliance pressure

-

Stringent standards demand tight process control and genealogy.

Stringent standards demand tight process control and genealogy.

Manual inspection

limits

-

Micro-defects and solder issues exceed human detection consistency.

Micro-defects and solder issues exceed human detection consistency.

Our Solutions

Electrical & Electronics Manufacturing Solutions

Connected operations with AI/ML, digital twins, and IIoT for higher quality, faster changeovers, and resilient supply chains.

Strategic Outcomes

Business Impact

Quantifiable gains in efficiency, uptime, and quality—driven by automation, predictive insights, and connected operations.

- +15–30% OEE via real-time visibility, line balancing, and automation.

- Higher first-pass yield and lower scrap/rework through AI-assisted inspection and SPC.

- Faster NPI & changeovers with digital work instructions and recipe management.

- End-to-end traceability for faster root-cause and compliant recalls.